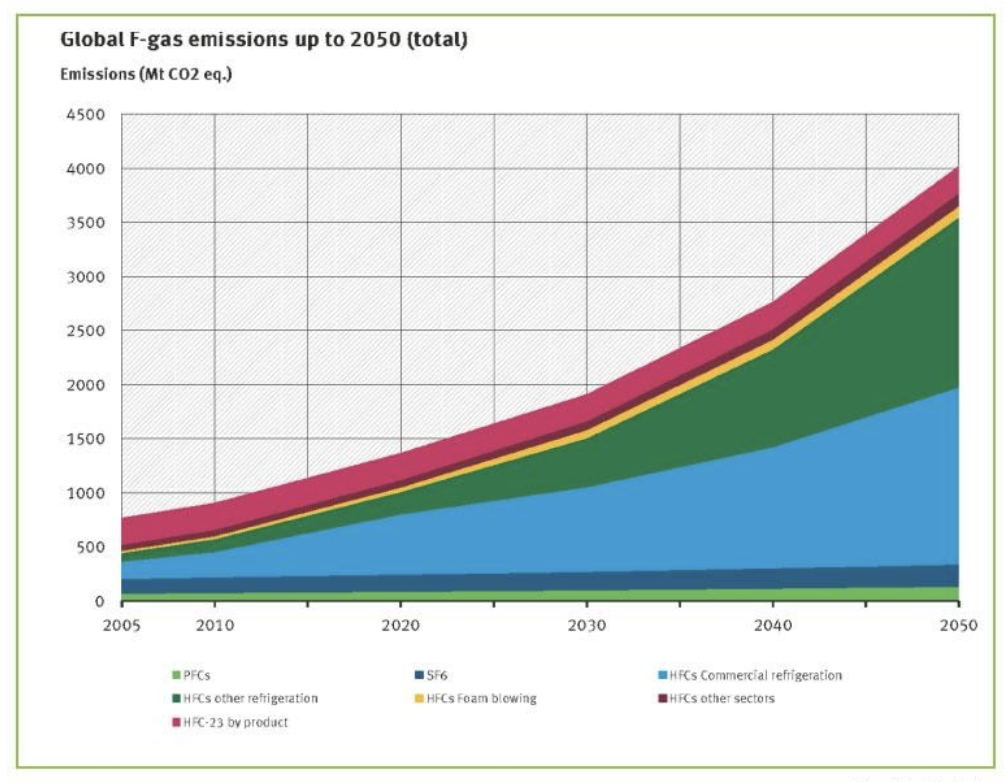

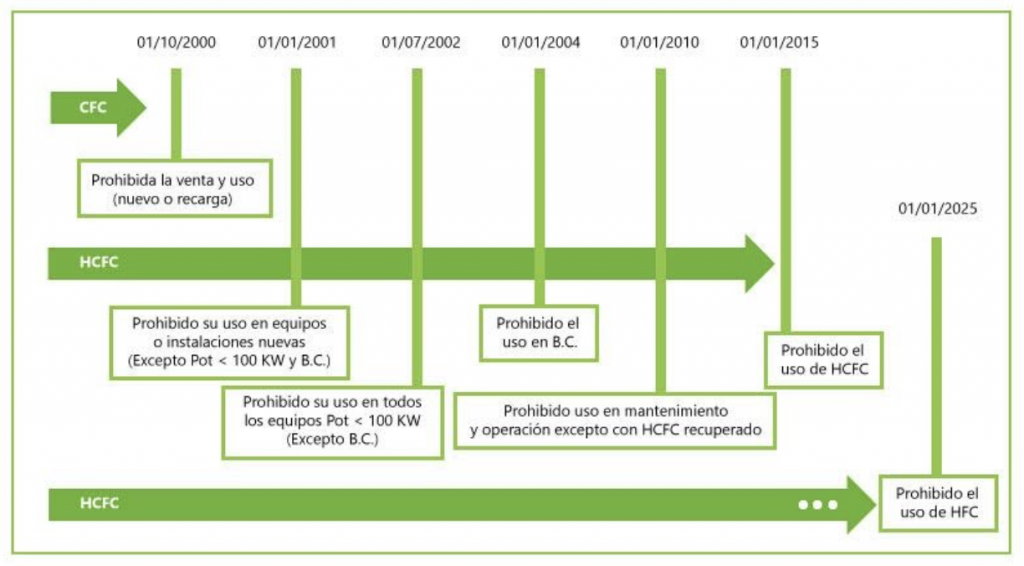

For all the aforementioned, the refrigeration sector is obliged to investigate and develop new alternatives that allow working with refrigerants with similar thermodynamic properties and zero GWP levels, in order to reduce greenhouse emissions into the atmosphere.

In the fourth generation of refrigerants are HFOs (hydrofluorolefins). According to D. Sánchez and I. Arauzo, these gases have good thermodynamic characteristics, although the cooling capacity is less than that of HFCs by at least 5%, they do not affect the destruction of the ozone layer and they have a very low GWP. Among the most prominent is the R32 and 1234ze. Both are considered A2L gases, that is, slightly flammable. Therefore, although there are some considerations for their use, they make them good alternatives to HFCs.

Investigations lead to the use of inorganic gases such as R717 (NH3 and CO2). Among the main advantages of these refrigerants we can highlight that they have thermodynamic yields around 3-10% higher than that of the aforementioned gases. In addition, the GWP and the ozone depletion potential is between 0 and 1, so at first glance they could be considered ideal gases for this sector. However, each of them has different disadvantages.

- NH3 (R717). It is not compatible with copper. In addition, it is a toxic and somewhat flammable component. This implies that the costs of equipment and facilities increase considerably before the need to increase security.

- CO2 (R744). The working pressures are much higher, which requires greater control of equipment and facilities, which increases costs. In addition, being heavier than air, it displaces O2 to dangerous levels for health. As it is odorless, the leaks are not noticeable. This causes that the securities are extreme and therefore the costs much higher.

Therefore, focusing the comparison between HFO and inorganic refrigerants, currently the trend tends to be positioned by HFOs, leaving inorganic ones destined for installations where the cooling capacity is very high.

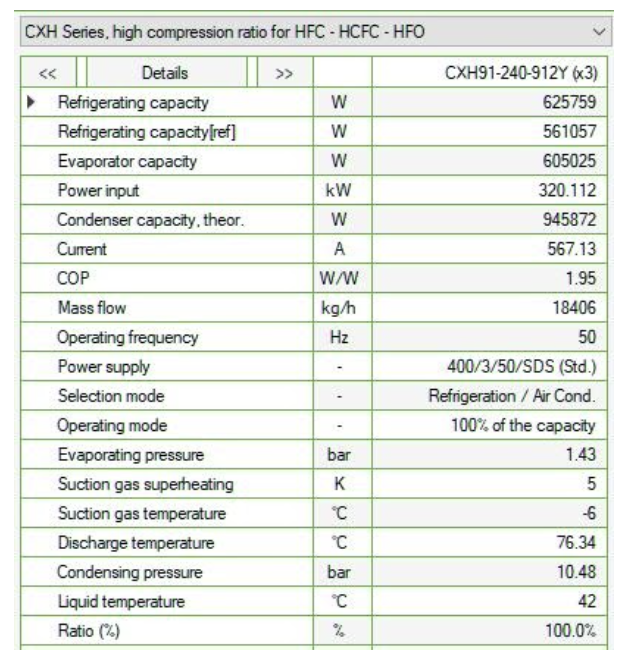

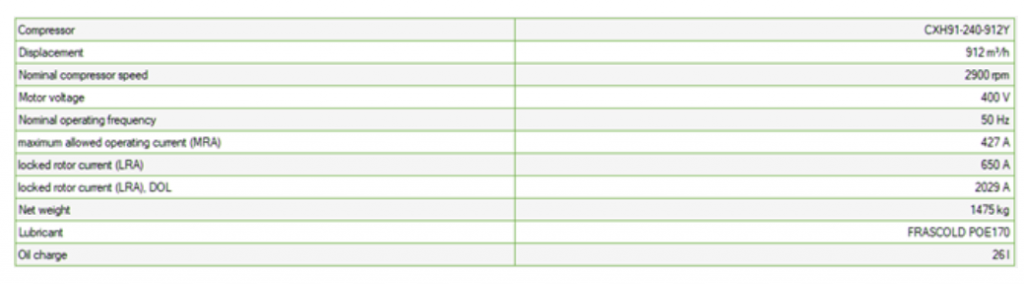

Throughout the article, a real case of a flatbed chiller with HFO refrigerant and the techniques used to reduce its energy consumption will be shown.