OUR VARIETY OF SUPPORT SERVICES

Research & Development

Innovative product development is key to Keyter’s success, setting HVAC+R standards when it comes to manufacturing expertise and addressing industry, economic and environmental challenges.

Disruptive technologies

At Keyter we don’t stand still. We listen to the market and we investigate disruptive technologies. A large proportion of our profits are re-invested in R&D and we constantly strive to move forwards and be ahead of the game. We also take our environmental responsibilities seriously and constantly look at ways to minimise the impact our products have on the planet.

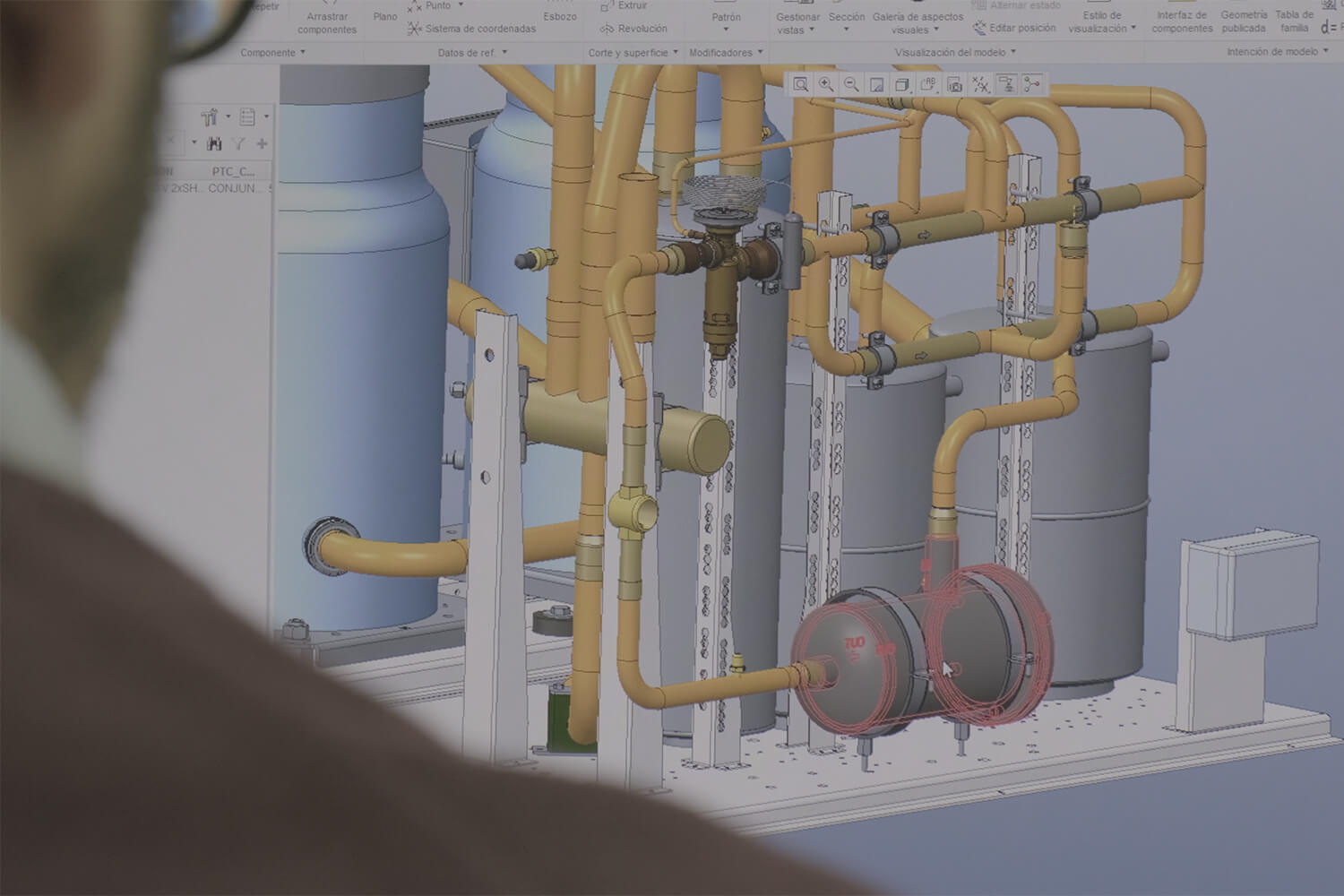

Innovative product development is key to Keyter’s success, setting HVAC+R standards and giving Keyter the edge when it comes to manufacturing expertise and addressing industry, economic and environmental challenges. We invest heavily on research and development to deliver continuously improving, cutting-edge cooling systems. Our state-of-the-art research facilities in the hands of our proactive, committed R&D team ensure that we are renowned for our pioneering approach to air conditioning product development and innovation, as each system is designed and developed with skill and care to maximize energy efficiency and optimize operational performance.

We manufacture a range of integrated systems with unrivalled quality and versatility. We use only the latest components from global leaders within their field such as Carel, Siemens and Terminal. We then apply each of these components to maximize the benefits and optimize the system performance, always working to stay at the forefront of energy efficiency and innovation.

For us, quality products rely on outstanding design. We use state-of-the-art techniques and development programmes to continuously improve products; we believe that quality is led by design and can only be achieved with large investment in R&D.

CAREERS

Want to be part of the Keyter family and

contribute to a greener world?

JOIN US!

“Our aim is to be visionary and never stand still in development leading-edge technology, energy efficiency and the environment”

Eva M Albarracín (Engineering Manager)

LONG TERM AIM

Continious improvement

Continuous improvement projects shape the future success of our quality and efficiency strategy. Keyter staff are trained and practice the following continuous improvement techniques:

Six Sigma

Value Stream Mapping

Lean Manufacturing

Root cause problem solving

We aim to involve all employees in one or more of the continuous improvement activities. Everyone has the opportunity to make decisions that affect their work, money, training, education, and development. Quality, innovation and continuous improvement strategies are employed in all business areas by everyone.

Keyter employees are encouraged to contribute to the decision making progress and as such are informed about company goals, objectives and activities. Everyone is encouraged to take responsibility for their actions, both to produce a good quality air conditioning product today and improve our products and services for tomorrow.

Innovation means improvements

We believe that improvement is always possible and we try to improve ourself and our products continuously. Not just our support and service, but in everything we do. Small improvements in the production process as well as big solutions to lower the energy consumption: we always try to make technical progress.

Thanks to our experienced R&D center and our focus to energy efficiency products we ensure you the solution you need. And because we produce our sustainable and low energy products in ‘the oven of Europe’ (Andalusia, Spain), we can test them under the most extreme conditions (heat and cold) to make sure the units perform optimal in your environment.

GET IN TOUCH

How can we help you?

Are you looking for (custom-made) HVAC+R solutions or do you have any questions?

Don’t hesitate to contact us