ROOFTOP – PERSEA EVO KCRA

persea evoKCRA

persea evoKCRAHigh-efficiency air-to-air rooftop units

|

inverter version |

|

euro version |

Rooftop units equipped with inverter compressor technology, electronic expansion valve, and variable-speed electronic fans to ensure maximum energy savings by minimizing the energy consumption of each application.

Exceeds the efficiency requirements of the Ecodesign Regulation

(ErP 2021) Average SEER of 5,2 – Average SCOP of 4

euro version

euro version

Rooftop units equipped with multiscroll compressor technology with tandem design, electronic expansion valve, and electronic fans, to achieve significant energy savings by optimizing the energy consumption of each application.

Exceeds the efficiency requirements of the Ecodesign Regulation

(ErP 2021) Average SEER of 4,7 – Average SCOP of 3,7

Adaptation and Environment

- Reduced refrigerant charge with low-GWP R-454B, minimizing CO₂ footprint (77% less GWP than R-410A and 31% less than R-32).

- Control of indoor air quality.

- Fully adaptable and configurable rooftops with optional features and a wide variety of installations.

Energy Efficiency

- Inverter technology to maximize seasonal energy efficiency.

- Optimized energy recovery systems for extracted air: Active Inverter Recovery – Dynamic Recovery

- Advanced control to increase seasonal efficiency by optimizing defrost management in the heat pump.

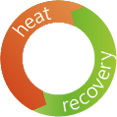

Active INVERTER heat recovery

Innovative Full Inverter Active Heat Recovery System for energy recovery through an additional refrigeration circuit with an inverter compressor.

This circuit allows for an increase in the unit’s nominal capacity, enhancing its compactness.

Additionally, since this extra circuit exchanges heat between the fresh air and exhaust air, under favorable temperature and humidity conditions, it achieves high cooling performance.

As a result, the unit’s nominal performance is improved, and seasonal efficiency is enhanced under partial loads.

Furthermore, the INVERTER technology ensures proper operation at the minimum air flow rates established by the 2021 RITE update, reducing the air flow from 1800 m³/h to 1000 m³/h.

Dynamics heat recovery

It consists of an energy recovery system using an additional exchange coil (subcooler), placed in series with the aircooled condenser of the unit. This setup significantly improves the unit’s efficiency by reducing the electrical consumption of the compressors.

This system offers advantages over static recovery systems because it avoids higher consumption by supply and return fans due to the high pressure drop associated with plate or rotary heat exchangers.

Additionally, it allows for installation in units with extraction fans.

Systems integration with

photovoltaic installations

- Intelligent energy management.

- The ability to manage and adjust optimal electrical consumption and thermal production capacity based on the available photovoltaic generation power at any given moment.

- It enables the integration of rooftops, heat pumps, and inverter chillers with photovoltaic installations.

Series 0 S

Series 1 S

Series 2 S

Series 3 S

Series 4 S

Series 5 S

Series 6 S

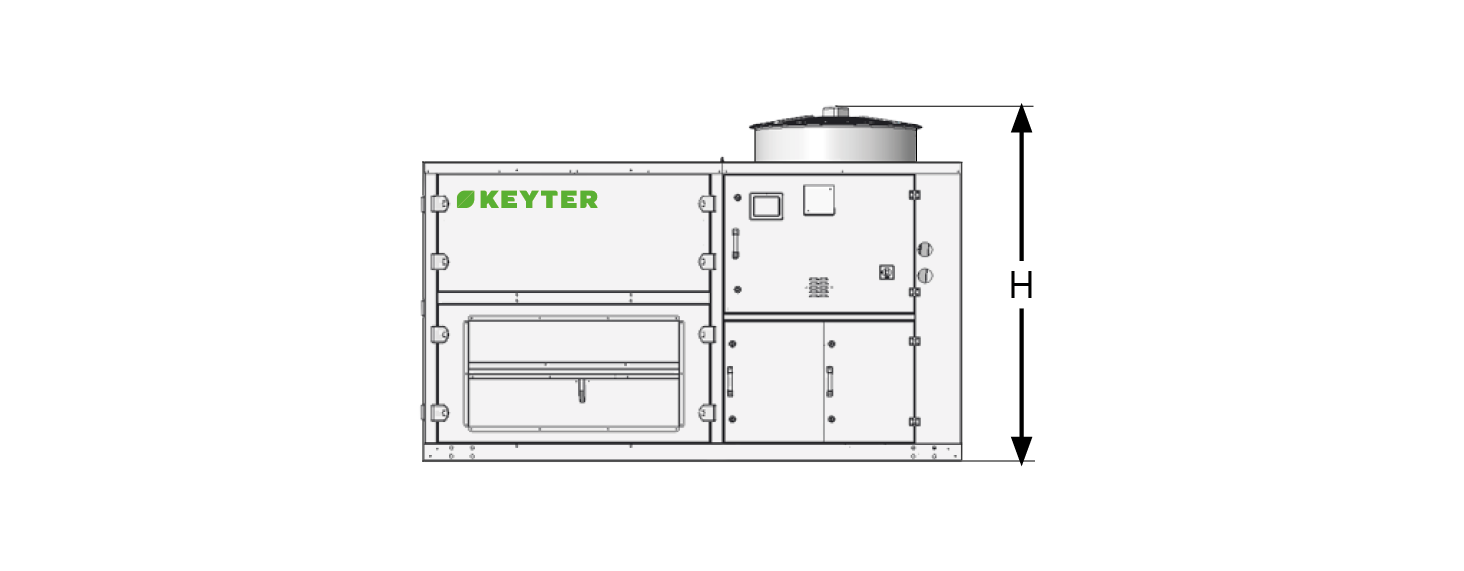

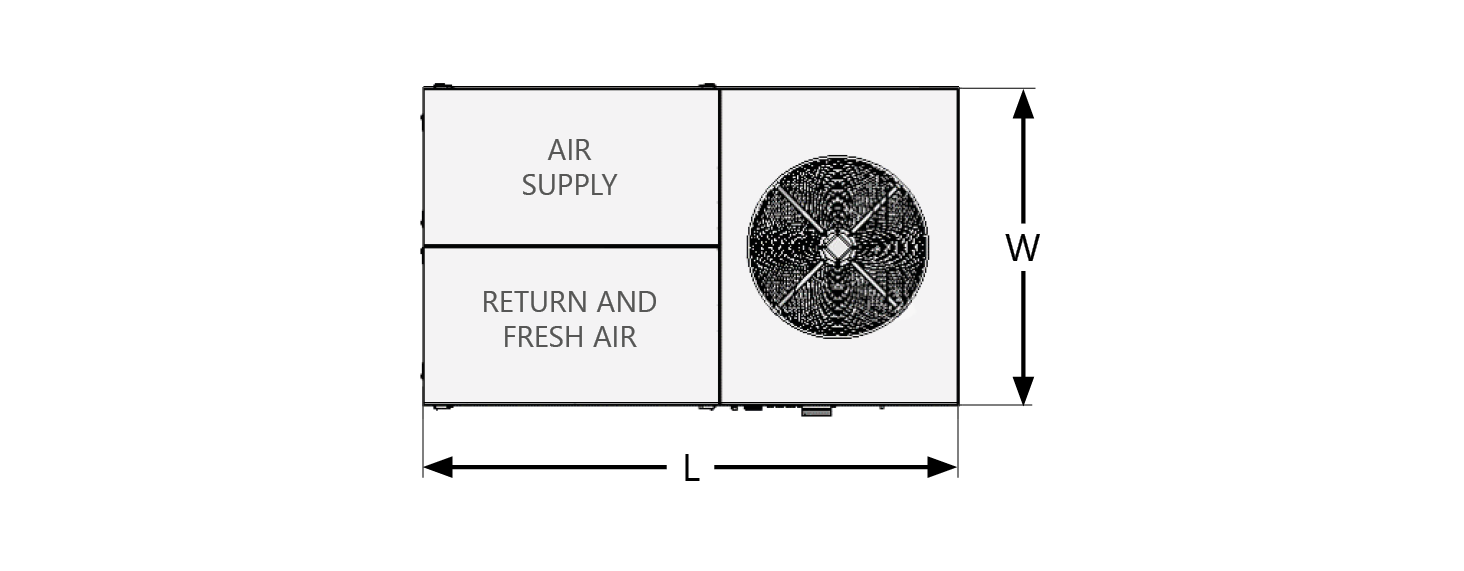

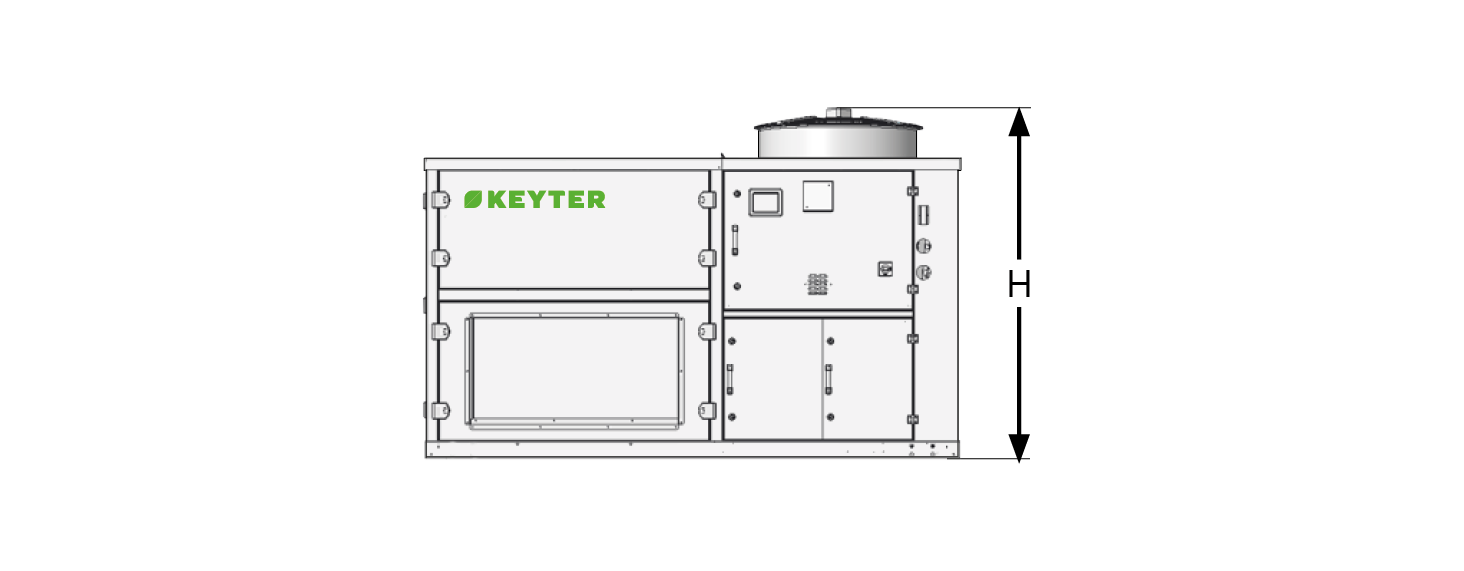

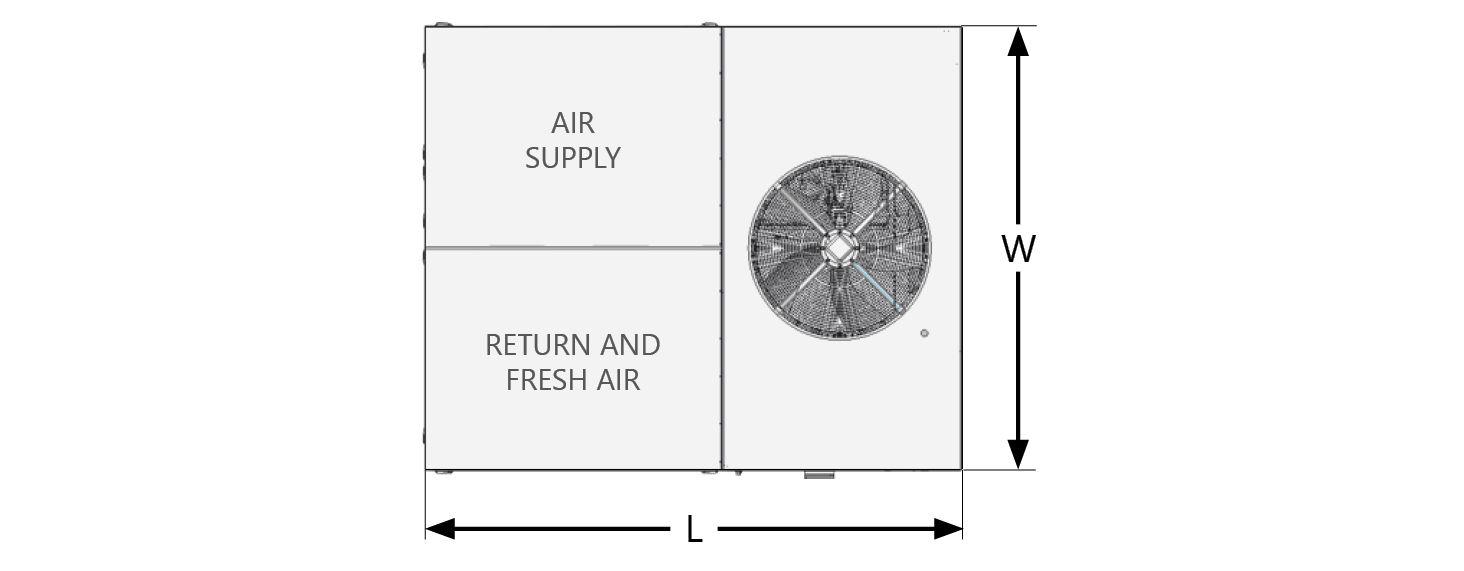

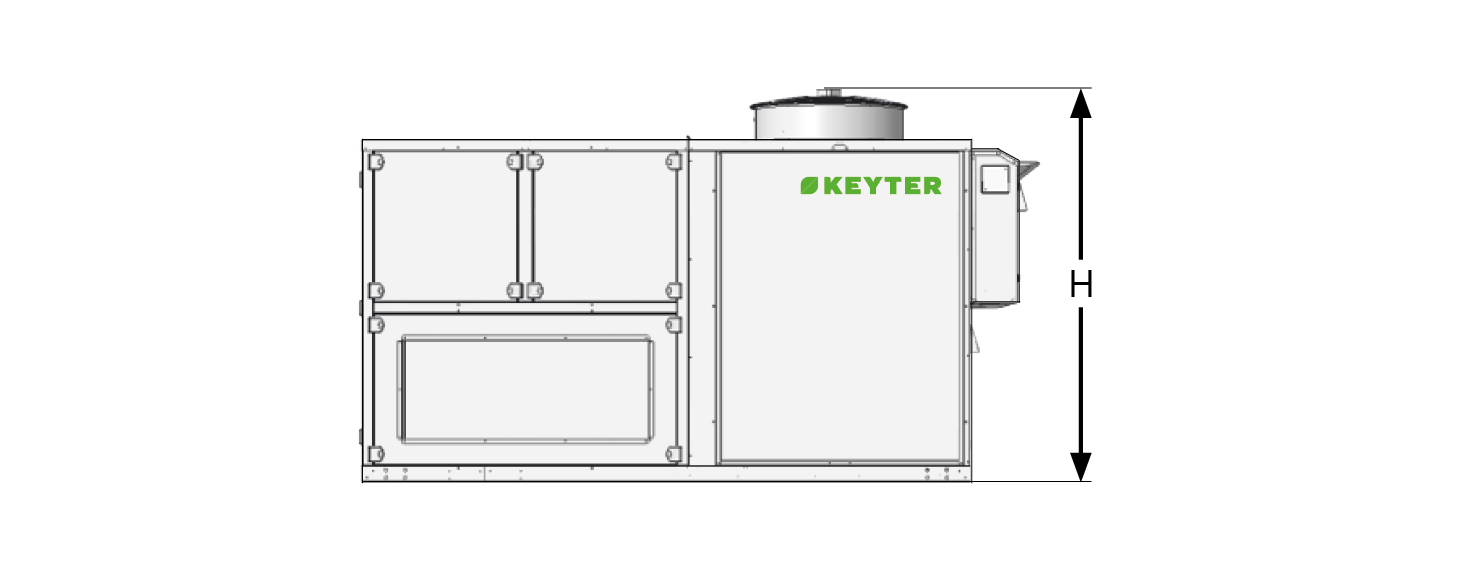

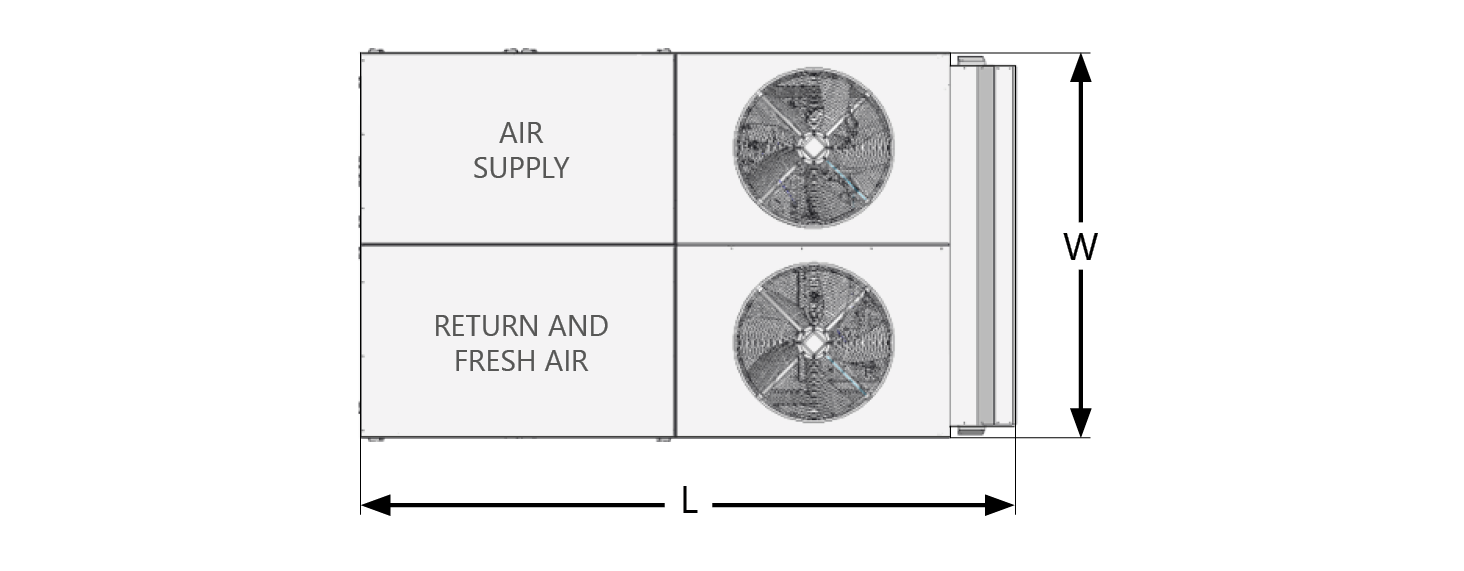

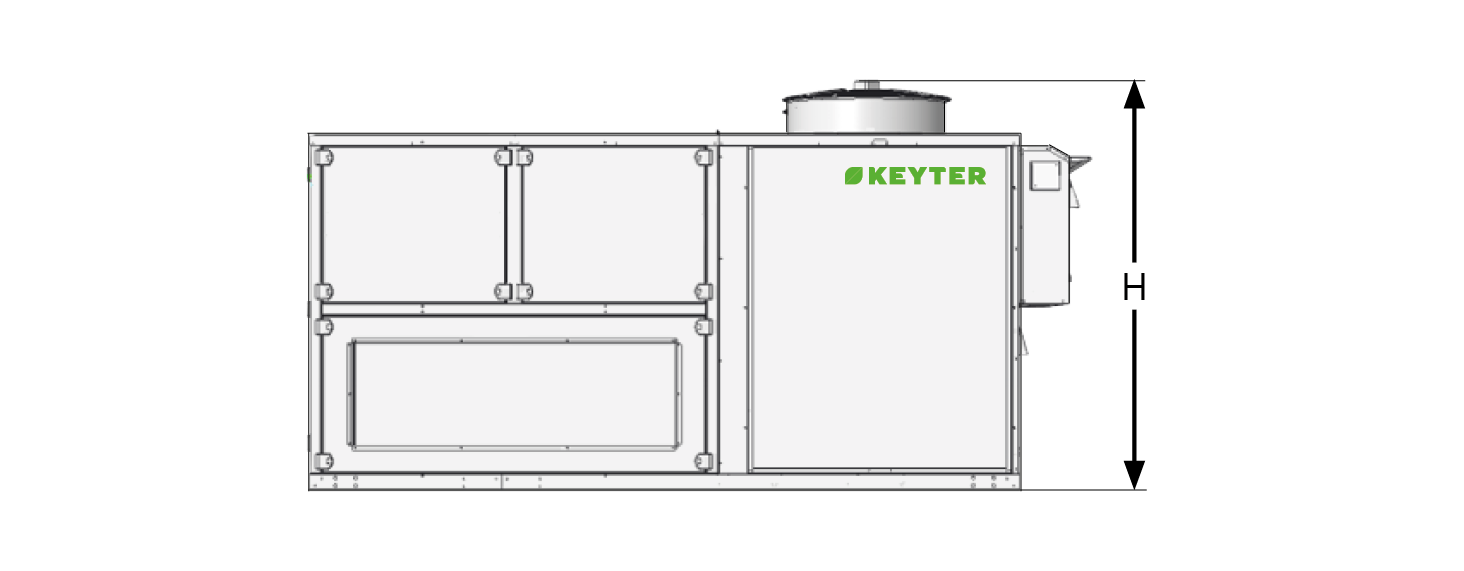

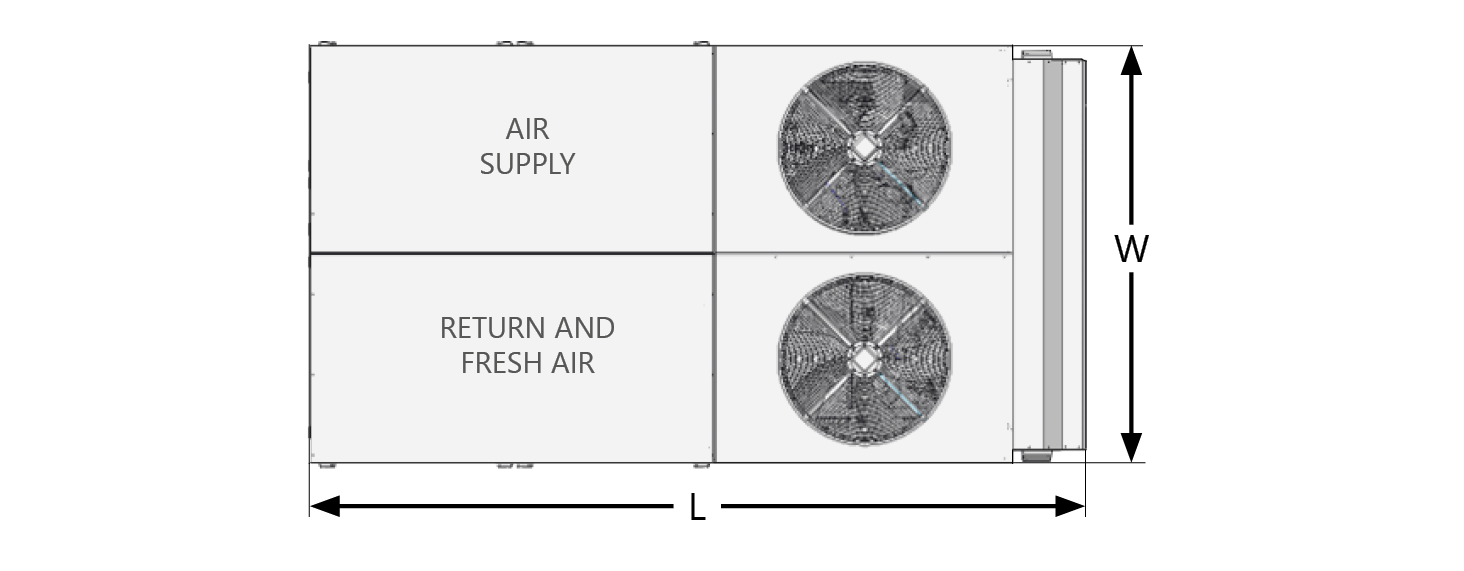

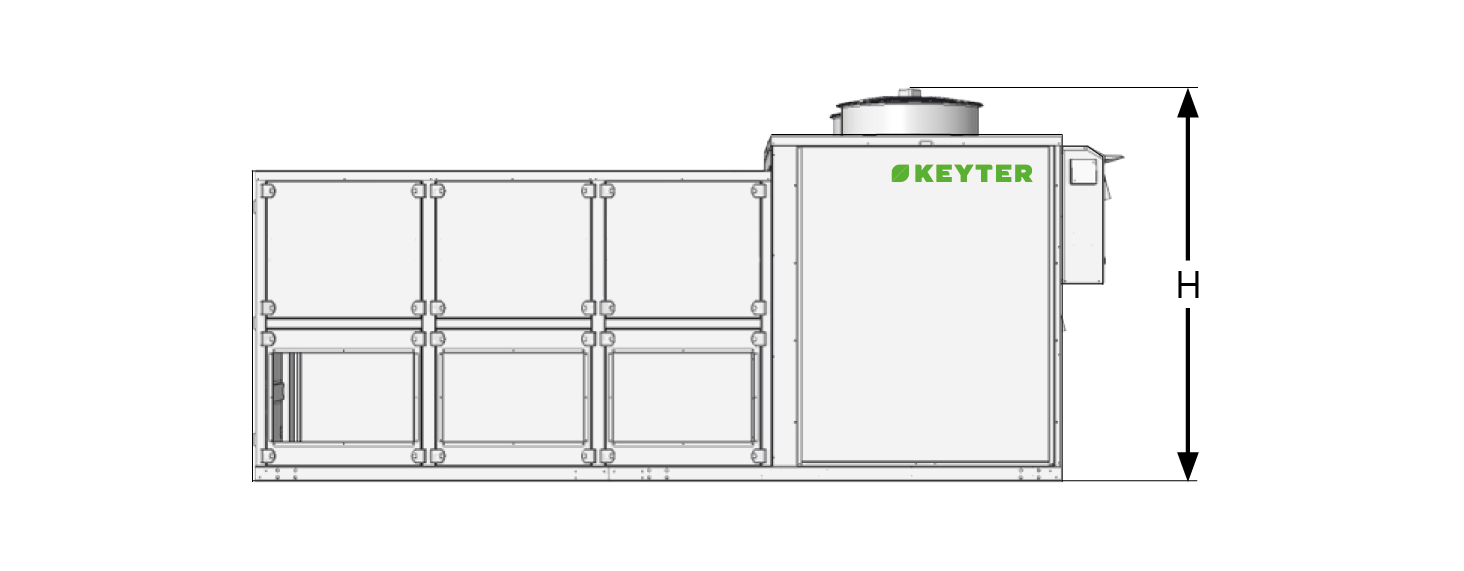

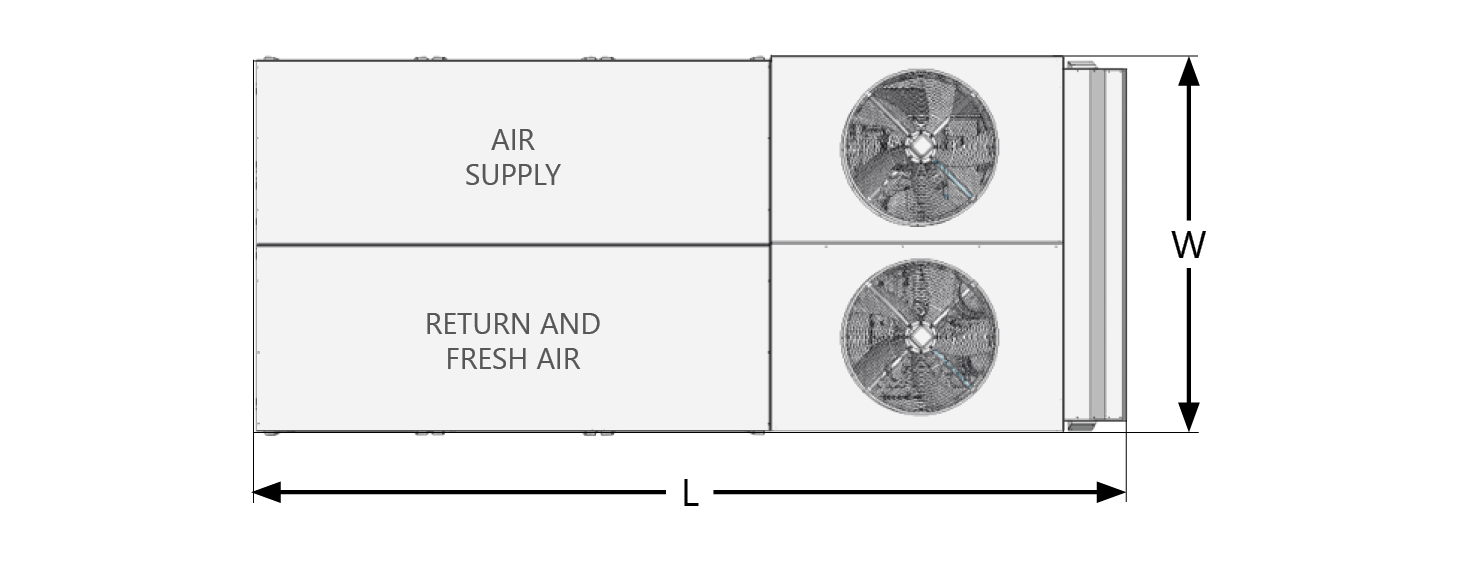

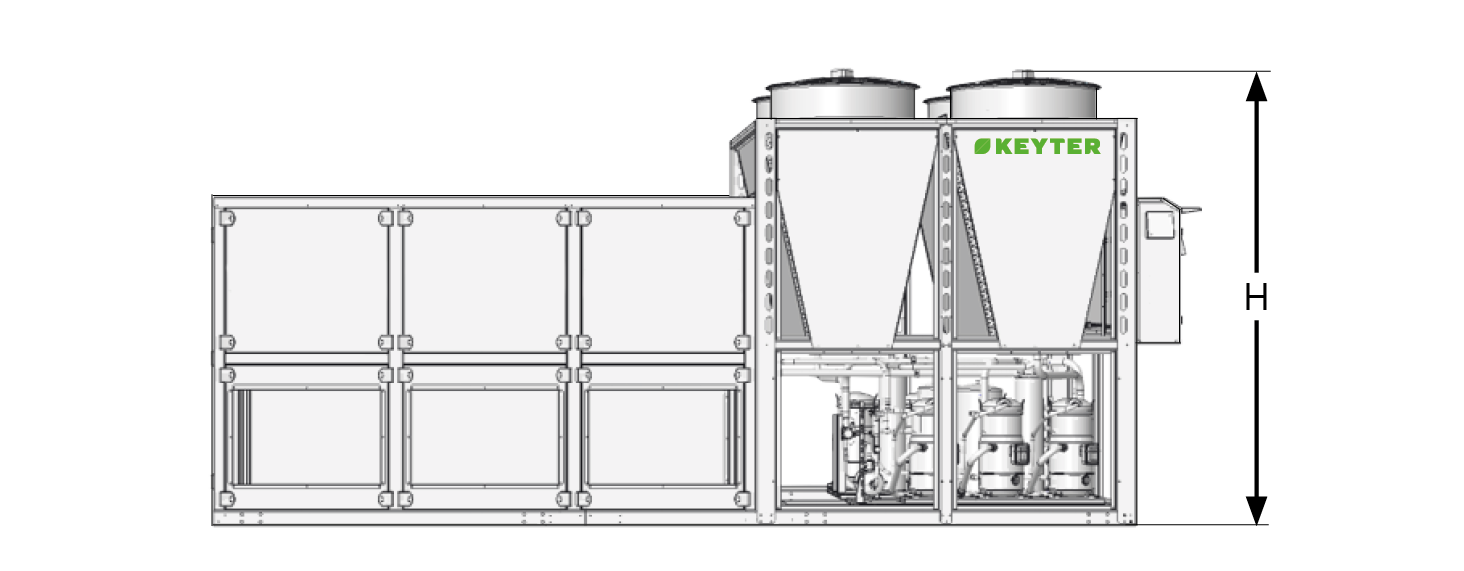

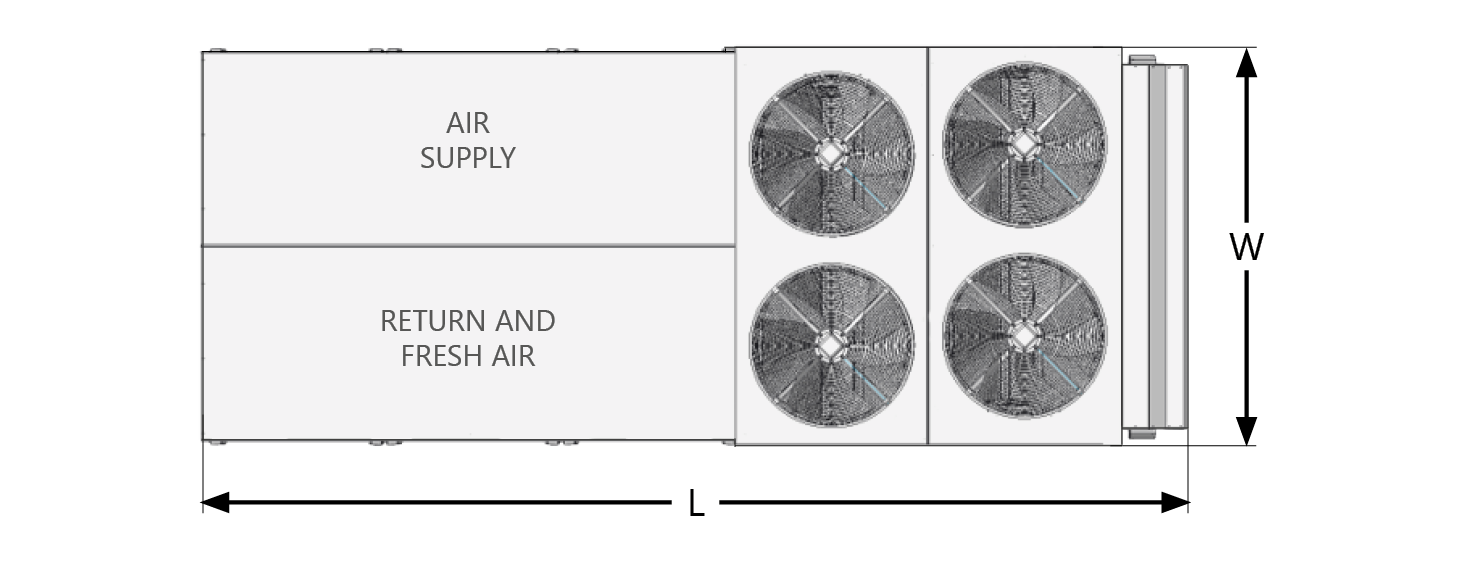

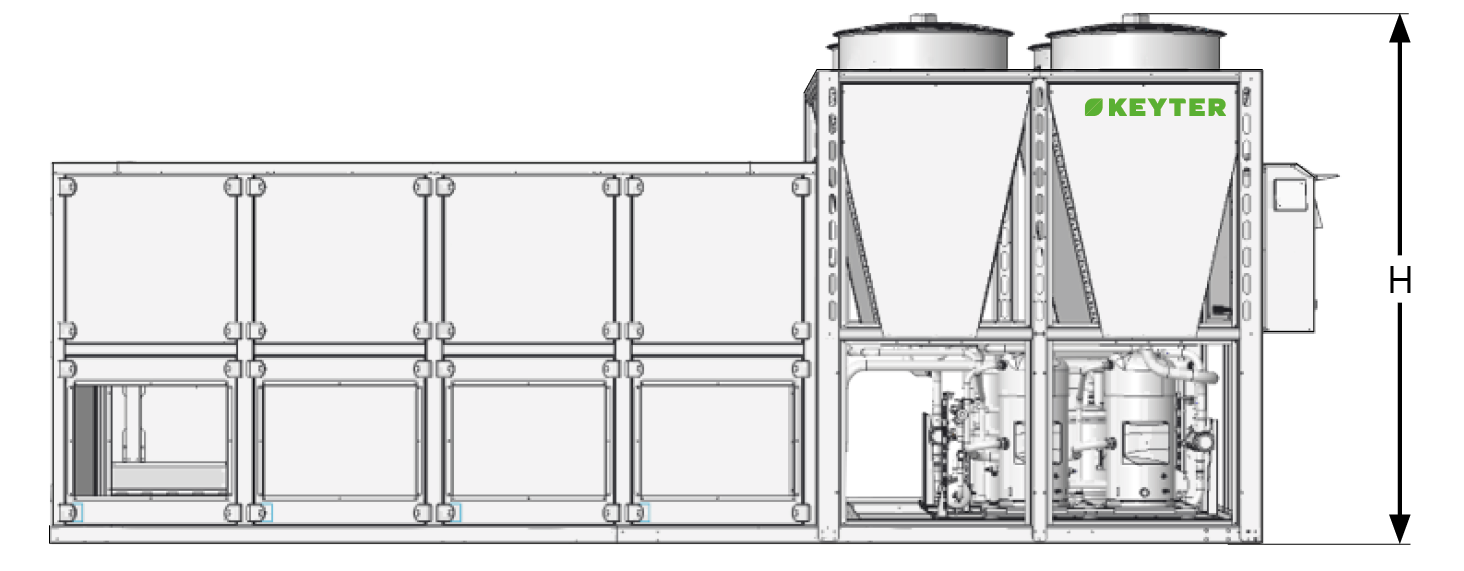

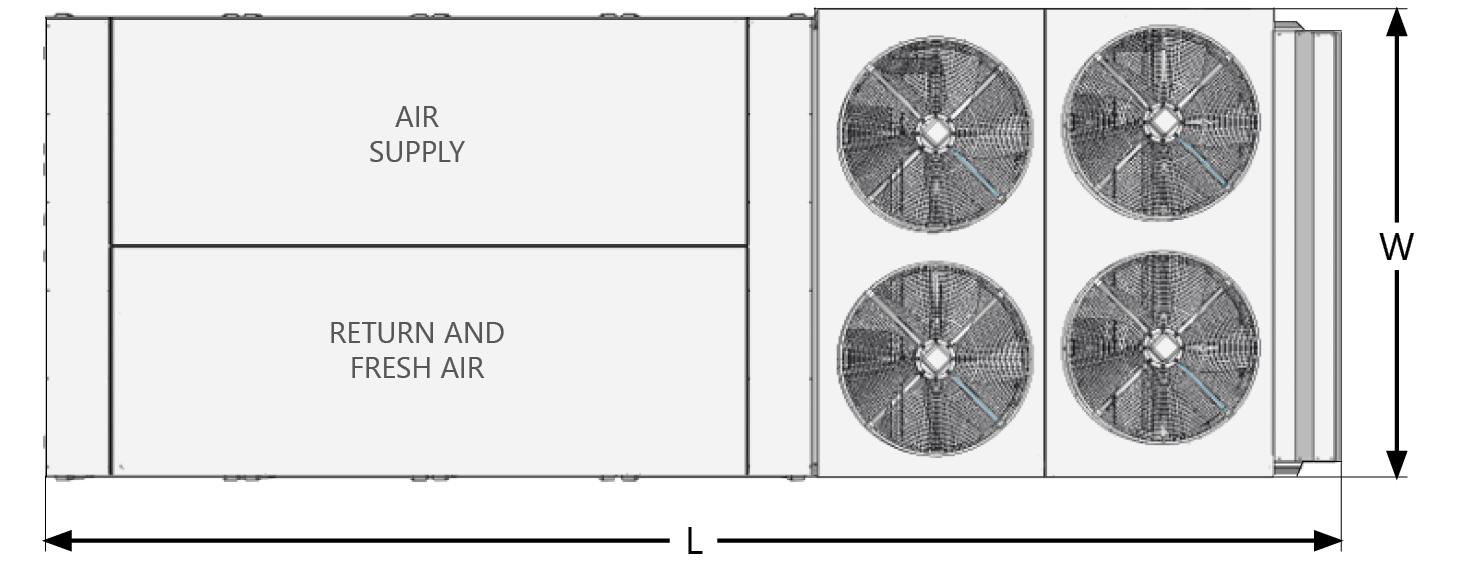

| Standard equipment dimensions (mm) | |||||||

|---|---|---|---|---|---|---|---|

| Series 0 | Series 1 | Series 2 | Series 3 | Series 4 | Series 5 | Series 6 | |

| L | 2575 | 2575 | 3600 | 3900 | 4950 | 5300 | 5910 |

| W | 1500 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 |

| H | 1730 | 1730 | 2060 | 2060 | 2260 | 2485 | 2485 |

| Dimensions of Equipment with Module (SC and SF Mounting) (mm) | |||||||

|---|---|---|---|---|---|---|---|

| Series 0 | Series 1 | Series 2 | Series 3 | Series 4 | Series 5 | Series 6 | |

| L | 2575 | 2575 | 3600 | 3900 | 4950 | 5300 | 5910 |

| W | 1900 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| H | 2135 | 2135 | 2465 | 2465 | 2465 | 2485 | 2485 |

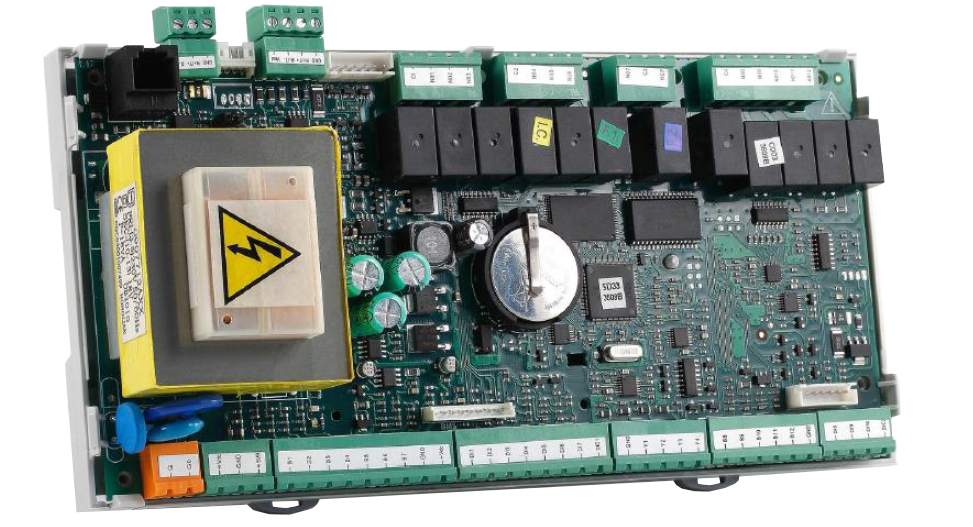

PERSEA EVO includes the programmable electronic control CLIMANAGER (μPC electronic control) and the user terminal pGD, compatible with the TH-Tune terminal.

It is compatible with optional RS485 card for Modbus communication and BACnet IP communication system.

GET IN TOUCH WITH US

How can we help you?

Are you looking for custom HVAC+R solutions or do you have any questions?

Feel free to contact us.