WATER-TO-WATER HEAT PUMPS – MEDEA KZV – KNV

medeaKZV

Water-to-water chillers and heat pumps

Documentation

Features

Specifications table

Views & Dimensions

Controls

Documentation

Features

Adaptation and Environment

- High-performance units equipped with plate heat exchangers that allow flexible configuration for centralized installations with a closed water loop and geothermal systems.

- Reduced refrigerant charge of low-GWP R-454B, minimizing the CO₂ footprint (-77% less GWP than R-410A and -31% less than R-32).

- Available versions with hydraulic group.

- Water production up to 60ºC.

- Maximum accessibility and easy maintenance through removable panels.

Energy Efficiency

- High energy efficiency in both partial and full load, reducing operating costs.

- Tandem multiscroll for improved seasonal energy efficiency.

- Units available with inverter compressors as an option for maximum energy efficiency.

- Electronic expansion valve for minimum energy consumption.

- Units with a hydraulic group can incorporate high-efficiency electronic pumps.

Specifications table

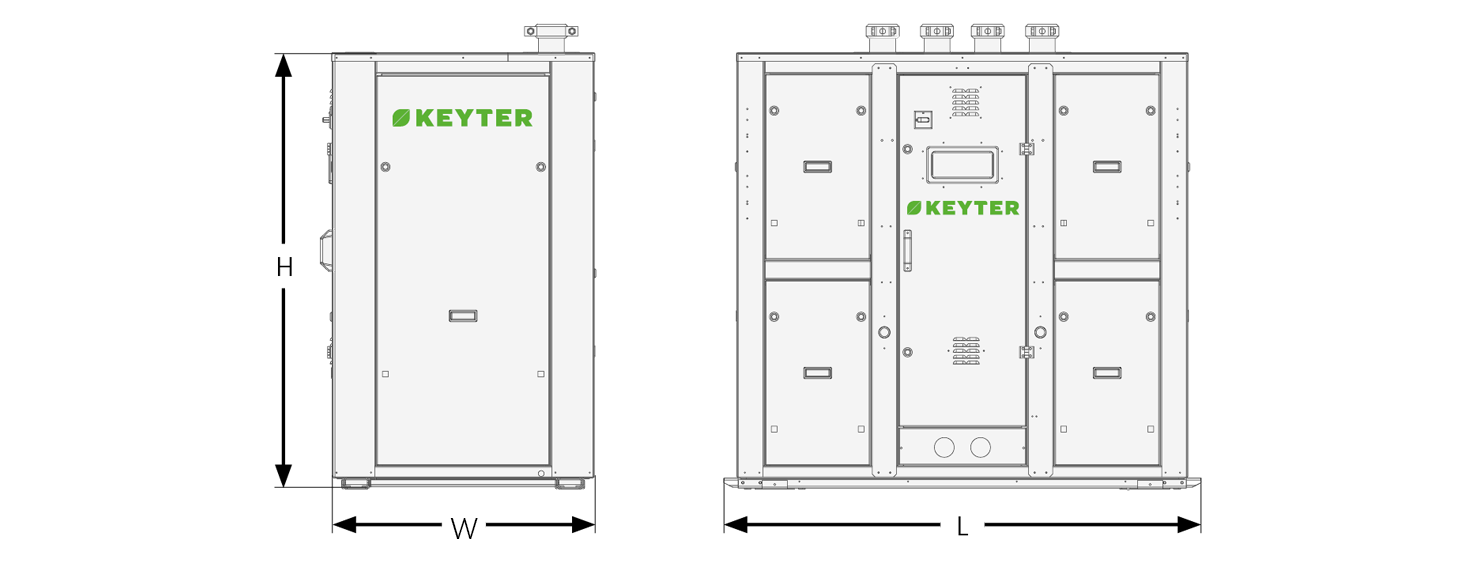

Views & Dimensions

| Dimensions (mm) Versions S / P / W / B |

Series 1 | Series 2 | Series 3 | |

|---|---|---|---|---|

| KZV models | All | KZV2035-KZV2120 | KZV2035-KZV2120 | All |

| KZVH models | KZVH2035-KZVH2100 | – | ||

| L | 900 | 1554 | 1554 | 2550 |

| W | 800 | 800 | 900 | 800 |

| H | 1267 | 1500 | 1500 | 1500 |

* Dimensions valid for models below 2090 with hydraulic versions P, W, and B.

Controls

MEDEA includes the programmable electronic control AQUAMATIX and the Climatix HMI user terminal.

It is compatible with optional RS485 card for Modbus communication and BACnet IP communication system.

GET IN TOUCH WITH US

How can we help you?

Are you looking for custom HVAC+R solutions or do you have any questions?

Feel free to contact us.