Industrial Air Conditioning

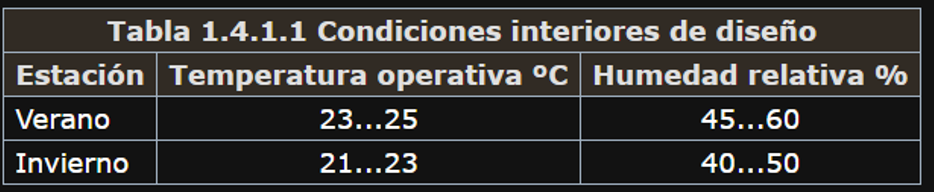

As is easily understood, in the industry the concepts of thermal and hygrometric comfort can be complex to achieve. Industrial buildings are not offices where these parameters are easily controlled and where metabolic levels are quite controlled. In fact, the ventilations provided by RITE (Regulation of Thermal Installations in Buildings), in a non-industrial regime, indicates a phrase that will serve as guidance:

This phrase is just before the forks where we must place ourselves at the level of temperature and humidity.

Obviously in industrial regime these conditions would not be met either in terms of 1.2met, or 0.5 or 1 clo, nor will we consider a PPD level of dissatisfied less than 10% and even less than the air velocity level 0.1 m / s. Arriving at this situation, for values outside these ranges previously stated, in environments regulated by RITE regulations we can rely on the UNE-EN ISO 7730, but for industrial environments … what do we do?

INDUSTRIAL ENVIRONMENT

In order to clearly explain we must define exactly how air conditioning would be regulated in Industrial Environments. At first, we can classify industrial environments as those that are not regulated according to the RITE (Regulation of Thermal Installations in Buildings) and are not considered residential. Likewise, it is not about other types of more specific environments such as the regimes to which hospital environments or controlled environment rooms such as clean rooms or clean rooms, for example, are subjected. Consequently, to deal with Air Conditioning in Industrial Environments we must rely on the Prevention of Occupational Risks.

THERMAL CONTROL

Thermal control is the “least complex” factor to control in industrial environments. In principle, it would be enough to maintain the temperature between 14 – 25 °C in jobs in case of people with non-sedentary activity and 17 – 27 ° C in sedentary people

In Industries you can air condition by refrigeration power by compressors or boilers, but given the volume of the workplaces, achieving something similar to thermal comfort would imply very high powers that would be really ruinous.

The cold is normally fought with thermal clothing, the stratification of the premises is a serious inconvenience, since the fan coils can reach the area occupied by operators, but they need a lot of speed of impulsion of the air dart.

But heat is a much more worrying and difficult aspect to treat in industrial environments.

The simplest system would be the placement of large diameter ceiling fans that would work in heat or cold mode, pushing down in winter and up in summer, breaking the stratification.

If the humidity levels in the environment are not worrisome, you can resort to adiabatic air conditioning. Thus, saturating the air with water by means of wet surfaces in the air conditioner, impulsion airs between 8 and 12°C are achieved below the outside air, if the humidity outside allows it.

This solution can be used as long as there is no risk of corrosion or deterioration of materials in the industry. In addition, this type of cooling involves very high air flows, so if it does not saturate the air too much preventing workers from evaporating, it can be functional by cooling and body evaporation. Adiabatic systems are the most effective when we are in large, open areas and where excess moisture is not a problem.

The physical process of adiabatic cooling is based on the cooling of air by evaporating water previously dispersed into the stream. To evaporate water in the air stream, the usual thing is the direct spraying of microdroplets of water. Wet panels can also be used by traversing them through the air stream. With this we achieve a decrease in its dry temperature and an increase in absolute and relative humidity.

The sequence of events is. The air undergoes a contribution of water, the air is moistened above the level of saturation of the air and the direct evaporation of the microdroplets of liquid water is caused. The energy for evaporation is obtained from the air stream which reduces its temperature.

Keyter offers a wide range of industrial air conditioners with this technology to adapt to the needs of each installation and guarantee the maximum comfort of its users. It is important that each project is studied by our experts and receives the necessary advice.

For places with more demanding air conditioning requirements, Keyter proposes to move to the use of traditional UTAs (Air Treatment Units or UMAs, Air Handling Units) and the distribution of the same through ducts or textile sleeves.

Textile ducts are an economical and very efficient solution for the conduction, distribution and diffusion of air in large industrial and commercial spaces. They are presented in various configurations and types of diffusion to adapt to the needs of each room or process. They are made of fabrics of high tensile and wear resistance, are very light, easy to install, modular, washable, customizable and can be installed up to a height of 30 m. Giving a good aérolico result, fruit of a previous study of diffusion case by case, diffusion of uniform air along the entire duct. Hygienically correct because they are composed of washable fabrics. Fabrics can be ordered as fire resistant, antibacterial, antistatic, etc

Keyter has among its product range the Titan Air Treatment Units of great versatility to adapt to the installation by offering a wide range of module possibilities. These are units with water batteries or direct expansion. Titan UTAs guarantee indoor air quality by having a high filtration capacity in compliance with IDAs. It is a high efficiency ventilation section by carrying plug&fan electronic fans with high pressure available and minimum energy consumption. They also incorporate energy recovery from the extraction air through a refrigeration circuit, rotary recuperator and cross-flow plate exchanger.

HYGROMETRIC CONTROL

Very complex to perform unless it is done directly with UTAs that dehumecten or moisturize according to demand. This aspect has few alternative solutions unless an injection of outside air helps us to lower high humidity.

CONTAMINANT CONTROL

So far non-existent, except in places with real risk to the worker.

According to the CLP Regulation “classification, labelling and packaging of chemical substances and mixtures”, art. 57, there are millions of chemical products, and many of them are dangerous to our health. We can find them in the form of simple substances (e.g. chlorine, sulfuric acid, asbestos, etc.) or mixtures when we are talking about two or more substances.

The combinations between the thousands of chemicals can be endless, and as a result, the mixtures number in the millions.

The definition of hazardous chemical given in RD 374/2001, art. 2, is one that may pose a risk to the safety and health of workers or to the environment due to its physicochemical, chemical or toxicological properties, and the way in which it is used or present in the workplace. As these agents in contact with the body can cause damage, they are also known as toxic products.

The doses to which workers are exposed must be monitored at all times and medical check-ups must be regularly monitored.

The effects can be very varied:

- Corrosive: they produce destruction of the tissues on which the toxic acts (e.g. chromium, nickel).

- Irritants: produce irritation of the skin (e.g. organic solvents and detergents), mucous membranes of the throat, nose, eyes (e.g. ammonia, formaldehyde) and lungs (e.g. nitrogen, phosgene, chlorine).

- Pneumoconiotic: they produce pulmonary alterations by depositing solid particles in their tissues.

- Asphyxiating: they reduce or make disappear the oxygen of the air of the environment that we breathe (eg carbon dioxide, nitrogen, hydrogen, ethane, methane) or prevent the cells of the organism from taking the necessary oxygen (eg hydrogen cyanide, carbon monoxide, hydrogen sulfide).

- Anesthetics and narcotics: they produce, in a general or partial way, the loss of sensation by action on brain tissues.

- Sensitizers: they produce allergic effects, even in small quantities (e.g. isocyanates, formaldehydes, phenolic resins, epoxy resins).

- Carcinogens, mutagens and teratogens: they produce cancer, hereditary modifications and malformations in the offspring, respectively.

- Endocrine disruptors: they alter the hormonal system causing damage to various organs and systems of both exposed people and their children.

Ventilation systems must keep these concentrations as low as possible, for this purpose the sources of contaminants, the emission levels and the reference values offered by the WHO must be identified. In this way we will obtain a ventilation rate for each of the contaminants and the sum of them will give us the correct ventilation.

SOURCES:

– Royal Decree 178/2021, of 23 March, amending Royal Decree 1027/2007, of 20 July, approving the Regulation of Thermal Installations in Buildings

– ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers)

– RISK PREVENTION IN THE WORKPLACE – Guide to trade union intervention

More articles

Interested in other (technical) knowledge articles? Keep yourself up to date and read them all.