INDOOR AIR QUALITY (IAQ) REVIEW: UNE 171.330

On May 22, the UNE 171.330 standard was published, focusing on the Indoor Air Quality (IAQ) Review, describing a methodology for carrying out an indoor environmental quality control plan. Unlike its predecessors, UNE 171.330-1:2008 and UNE 171.330-2:2014, which aimed at Diagnosis and Inspection, respectively.

The scope of application remains unchanged, excluding industrial and agricultural activities. It also refers to the application of UNE 171.340 for Controlled Environment Zones in Hospitals and UNE 171.350 for Hospitality Establishments.

To correctly apply the standard, it is essential to understand the classification of HVAC equipment in HVAC (Heating, Ventilation, and Air Conditioning) installations:

Type A HVAC Equipment

Air treatment units for large surfaces, powered by centralized systems. Known as AHUs (Air Handling Units), they generally include most stages described for such equipment. They are usually associated with All-Air units or fresh air supply units in mixed Air-Water systems.

Type B HVAC Equipment

Air treatment units with thermal capacities between 5 and 20 kW (in cooling or heating). They are typically intended for medium-sized areas and usually correspond to compact systems that include cooling and heating production elements within the same unit (Rooftop units, autonomous units, etc.).

Type C HVAC Equipment

Air treatment units with thermal capacities below 5 kW (in cooling or heating). They are typically small units used for fine temperature adjustment in specific areas of a given zone. They include fan coil units, VRF units, indoor heat pump units (split type), window units, etc.

Type D HVAC Equipment

Ventilation units without heat exchange batteries, such as energy recovery units.

IAQ CONTROL PLAN PROCESS

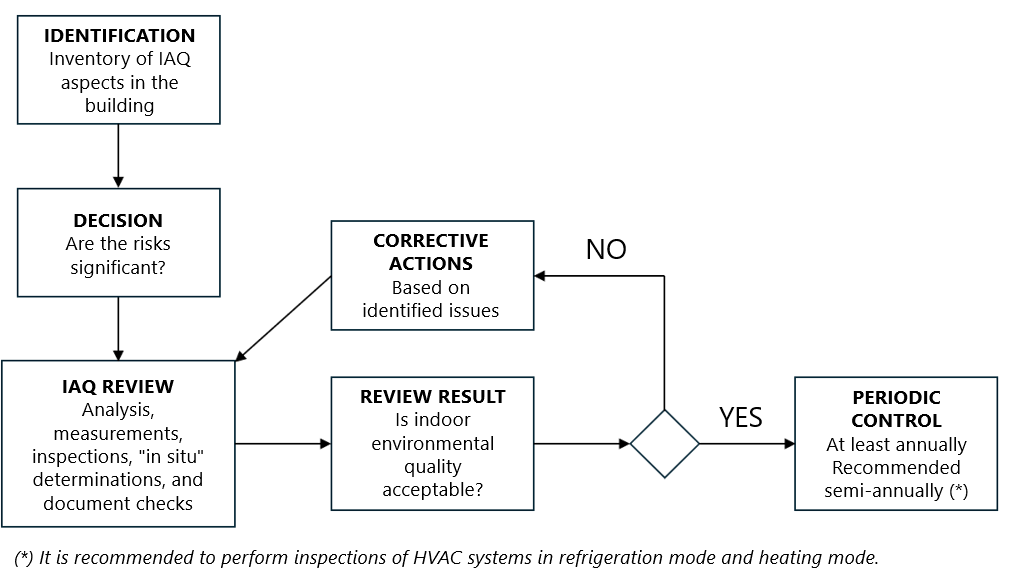

The IAQ control plan for a building consists of the following phases:

- IDENTIFICATION: Identification of variables that may affect IAQ. A list is provided without any type of evaluation or analysis.

- DECISION: At this stage, the IAQ Specialist (TSCAI) evaluates, through visual inspection and/or document data review, which of the identified aspects may have a significant influence on indoor environmental quality.

- REVIEW: When a specific environmental aspect is deemed significant, the actual risk is assessed through an IAQ REVIEW. This stage requires more detailed inspections, sampling, and laboratory analysis.

- RESULT: The values obtained in the review are compared with the values established by this standard, resulting in either a CONFORMING or NON-CONFORMING result.

- CORRECTIVE ACTIONS: If the result is non-conforming, the causes must be identified, and appropriate corrective actions must be defined. Once these actions are implemented, a new assessment must be conducted until a CONFORMING result is achieved.

- PERIODIC CONTROL: Environmental quality must be monitored at least annually; however, it is recommended to do so biannually, coinciding with seasonal changes (cold/warm seasons).

As indicated by the standard, the flowchart to be followed is as follows:

Brief description of each step in the flowchart:

IDENTIFICATION

Some of the most important aspects that affect IAQ are as follows:

- Building location.

- Uses, activities, schedules, and layout of the building.

- Construction and decoration materials.

- Building systems (HVAC systems, water installations, sanitation installations, etc.).

- Building maintenance.

- Building remodeling.

- Building users.

DECISION

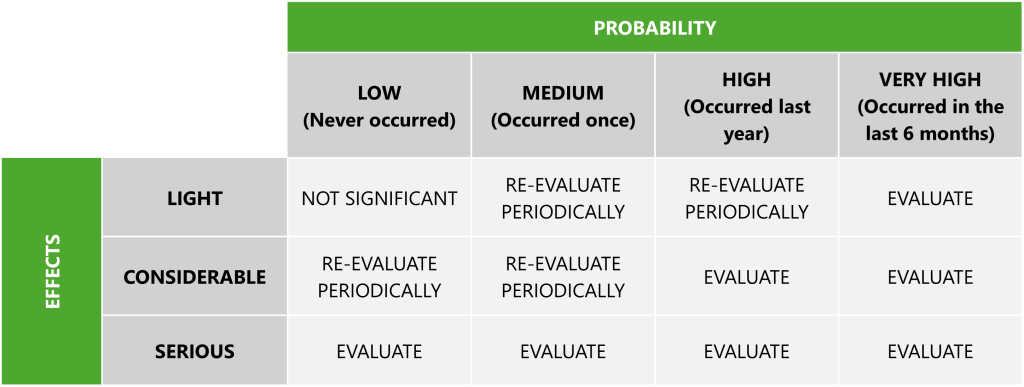

This involves determining whether the risk associated with these aspects should be evaluated (Quantifying the potential negative effect on IAQ through analysis, direct measurements, and/or visual inspections).

The risk matrix (probability/effects) used is as follows:

Effects are classified as follows:

- Light Effect: Implies alterations that, due to design factors, material deterioration, type of contaminants involved, and/or expected values, do not pose significant damage or major imbalances in indoor environmental quality, nor have immediate repercussions on users. Requires medium/long-term corrective actions, up to several years. It is recommended not to exceed 3 years.

- Considerable Effect: Would cause significant damage to indoor environmental quality and/or affect user comfort. Requires short-term corrective actions, within a few months. It is recommended not to exceed 6 months.

- Serious Effect: Would cause severe damage to indoor environmental quality and likely impact user health. Requires immediate corrective actions. It is recommended not to exceed 1 month.

REVIEW

With the significant environmental aspects evaluated, an assessment must be conducted using tests, direct measurements, visual inspections, and/or document reviews. These actions will determine if the potentially negative situations are actually affecting IAQ.

It is mandatory to perform at least one measurement of all mandatory minimum parameters outdoors.

The mandatory minimum parameters to be analyzed are, at least annually:

- Hygienic evaluation of air treatment systems.

- Dry temperature and relative humidity.

- Carbon dioxide.

- Carbon monoxide.

- Particulate mass (PM2.5).

- Particulate count (sizes 0.5 and 5 μm).

- Aerobic mesophilic flora in suspension (bacteria).

- Fungal flora in suspension (fungi).

- Total volatile organic compounds (TVOCs).

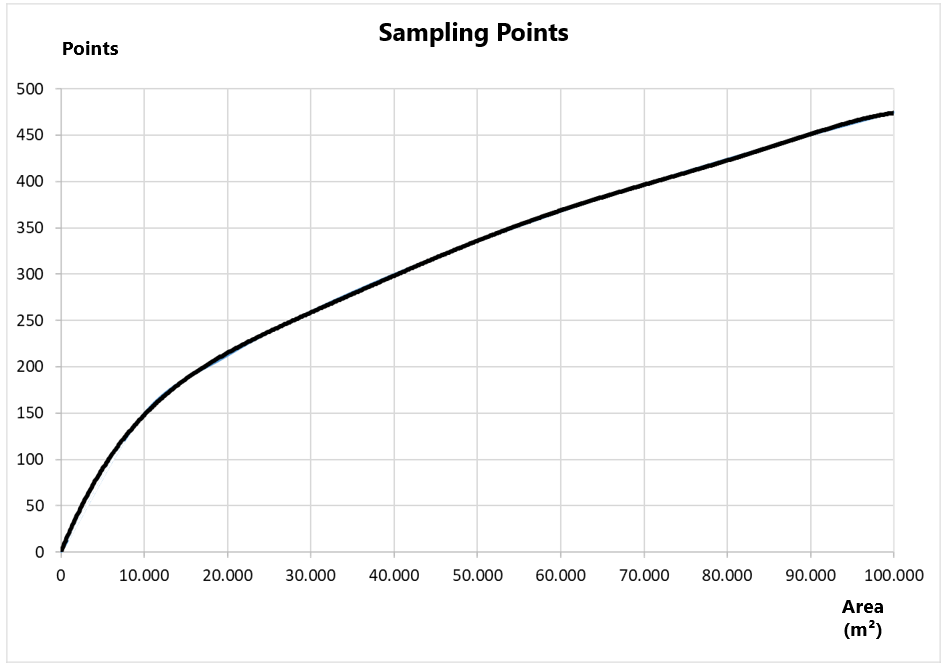

A minimum number of sampling points in the building for mandatory parameters is established.

Optionally, at the discretion of the TSCAI, the following can also be evaluated:

Fungi and bacteria in the ducts, formaldehyde, ambient lighting, noise, electromagnetic fields, static electricity, nitrogen oxides, fiberglass, ozone, thermal comfort analysis (UNE EN ISO 7730), sulfur dioxide, radon gas, allergens and sensitizers, endotoxins, and mycotoxins.

HYGIENIC EVALUATION OF AIR TREATMENT SYSTEMS

For each type of system (A, B, C, or D), the following tests must be conducted:

HVAC EQUIPMENT (TYPES A, B, C, AND D)

- Visual inspection (including photographic documentation).

Additionally, for Type A systems, a microbiological contact sample (bacteria and fungi) must be taken from the heat exchange coil (preferably the cooling coil).

SUPPLY AIR DUCT. SUPPLY AND EXHAUST AIR DUCT

- Visual inspection (including photographic documentation).

- Microbiological sampling (bacteria and fungi) from the surface.

- Dust sampling by two complementary techniques: aspiration test (cassette) and adherence test (adhesive strip).

At least 25% of AHUs must be inspected, with equipment rotation to cover all units within 4 years.

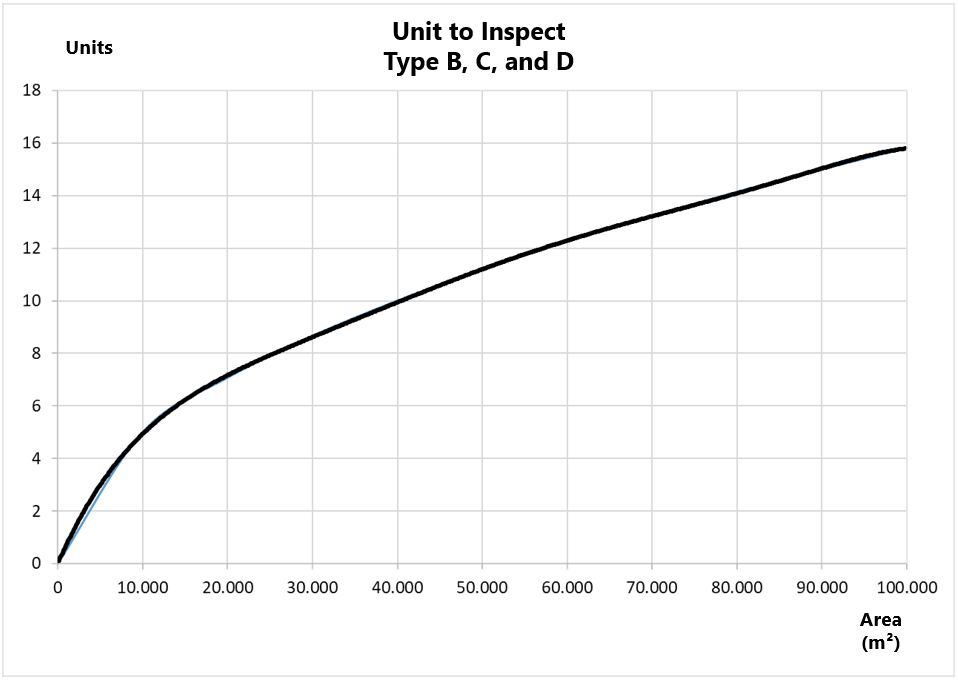

Systems B, C, and D will be inspected according to the law.

Indoor environmental quality is based on two criteria:

Acceptable Value: A value intended to preserve the well-being and health of occupants, depending on IDA.

Maximum Limit Value: Represents a concentration or absolute value that must never be exceeded. If exceeded, even once and for a single parameter, it would result in a complete non-conformity of the building or installation.

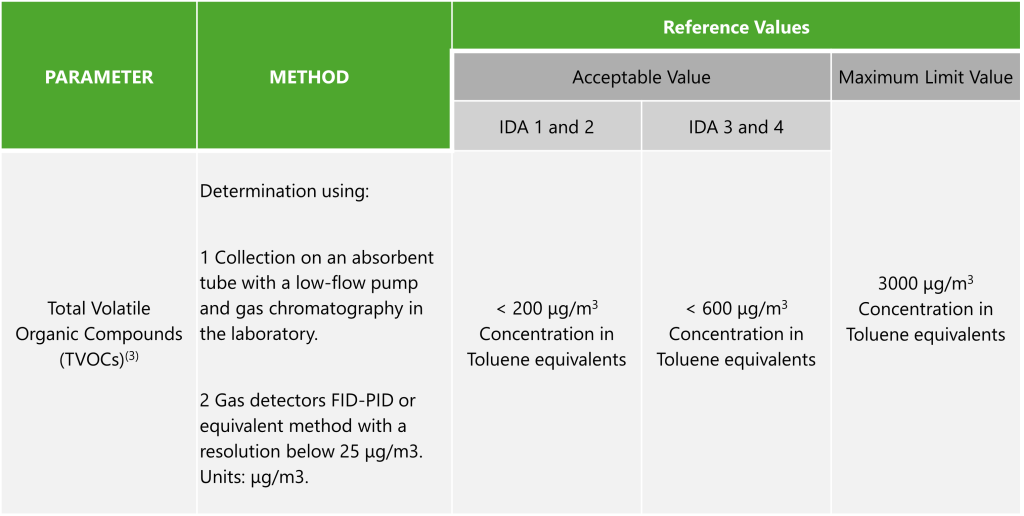

These values are listed in Table 7 of the UNE standard. Below, we present the reference values for Total Volatile Organic Compounds (TVOCs).

(3) If the Acceptable Value is exceeded at any point, it is recommended to identify TVOCs by collection on an absorbent tube and laboratory analysis (Annex C).

REVIEW RESULT

A building is considered conforming if it meets the following requirements:

- For mandatory parameters, at least 75% of the points for each parameter must be below the Acceptable Values.

- If there is a non-conformity in any parameter, but the cause has been identified and corrective actions have been proposed.

- None of the measurements exceed, at any point, the Maximum Limit Value.

More articles

Interested in other (technical) knowledge articles? Keep yourself up to date and read them all