Estimation Of Maximum Allowable Load For Refrigeration Systems

Although the F-Gas regulation may seem highly technical and complex, at KEYTER, we strive to simplify it for our clients. We offer a 360º service where our specialized technical teams analyze each project individually, providing tailored advice to ensure the best HVAC solutions. Clients who trust KEYTER can rest assured that they will comply with all regulations while optimizing the efficiency and sustainability of their installations. Below, we outline the key points to accurately calculate the maximum allowable refrigerant load in refrigeration systems.

The implementation of Regulation (EU) 2024/573 of the European Parliament and the Council, dated February 7, 2024, concerning fluorinated greenhouse gases, which amends Directive (EU) 2019/1937 and repeals Regulation (EU) No. 517/2014, has reshaped the way HVAC and DHW systems are perceived.

Refrigerants used in our installations have shifted from being classified within Group L1 (A1), L2 (B1, A2L, B2L, A2, and B2), and L3 (A3 and B3). This shift makes flammability a crucial factor when designing an installation, particularly regarding the equipment’s placement.

The Royal Decree 552/2019 of September 27, which approves the Safety Regulations for Refrigeration Installations and their complementary technical instructions, in its Instruction IF-04 – Use of Different Refrigerants, specifies the following in section “3.2 Maximum allowable refrigerant load in general”

To determine this load, the following factors must be considered:

- Refrigerant toxicity category.

- Refrigerant flammability category.

- Classification of the space based on accessibility, as per Article 7.

- Type of location, according to Article 6.2.Veamos cada uno de estos puntos.

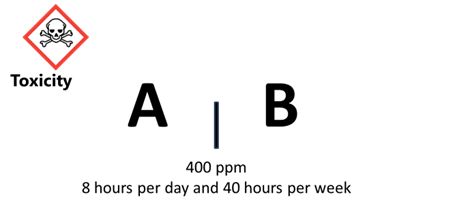

TOXICITY CLASSIFICATION

The RSIF defines toxicity as the “property of a substance that makes it harmful or lethal to humans and animals due to intense or prolonged exposure through contact, inhalation, or ingestion.”

Two toxicity categories are established: Category A and Category B:

“Refrigerants should be placed in one of the categories A and B on the basis of their toxicity:

CATEGORY A:

Refrigerants whose time-averaged concentration has no adverse effect on the majority of workers who may be exposed to the refrigerant during a working day of 8 hours per day and 40 hours per week and whose value is equal to or greater than an average concentration of 400 ml/m3 (400 ppm (V/V)).

CATEGORY B:

Refrigerants whose time-averaged concentration has no adverse effect on the majority of workers who may be exposed to the refrigerant during a working day of 8 hours per day and 40 hours per week and whose value is less than an average concentration of 400 ml/m3 (400 ppm (V/V))”.

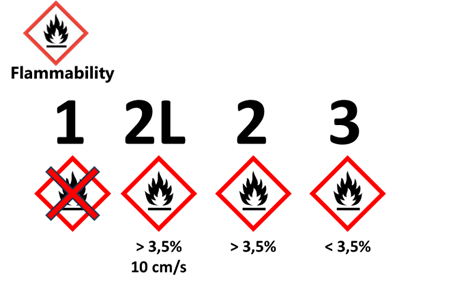

FLAMMABILITY CLASSIFICATION

RSIF does not define flammability, but we can associate it with the ability of a refrigerant to propagate a flame in a homogeneous mixture of air and refrigerant.

For this purpose four Flammability Categories are created, Category 1, 2L, 2 and 3.

“Refrigerants shall be placed in one of three categories, 1, 2 and 3 on the basis of the following:

CATEGORY 1:

Refrigerants showing no flame spread when tested at +60°C and 101.3 kPa.

CATEGORY 2:

Refrigerants meeting the following three conditions:

Show flame spread when tested at +60°C and 101.3 kPa.

They have a lower flammability limit, when mixed with air, equal to or greater than 3.5% by volume (V/V).

It has a heat of combustion of less than 19,000 kJ/kg.

Within this group, ISO 817 has introduced the criterion of reduced risk due to the low flame propagation speed of certain substances, establishing the category 2L, which in addition to satisfying the three previous conditions has the following characteristic:

Flame propagation speed lower than 10 cm/s.

CATEGORY 3:

Refrigerants meeting the following three conditions:

Show flame spread when tested at +60°C and 101.3 kPa.

They have a lower flammability limit, when mixed with air, of less than 3.5% by volume (V/V).

Has a heat of combustion greater than or equal to 19,000 kJ/kg”.

As can be seen, Category 2L was introduced after the initial categorisation.

ACCESSIBILITY CLASSIFICATION

Ease of access to the building, mobility within the building and knowledge of occupant safety measures define Building Accessibility.

“Article 7. Classification of premises according to their accessibility.

On the basis of safety criteria, the premises (enclosures, buildings or parts of buildings) in which refrigeration plant is located are classified into the following categories:

a) Category A. General access: Rooms, enclosures or buildings where:

(i) persons are limited in their ability to move.

(ii) the number of persons present is not controlled.

(iii) anyone can gain access without necessarily being aware of the security precautions required.

b) Category B. Supervised access: Rooms, enclosures or buildings with a limited number of people, some of whom must necessarily be familiar with the general safety precautions required of the establishment, mainly the location of emergency exits and passageways.

c) Category C. Authorised access: Rooms, enclosures or buildings to which only authorised persons have access, who are aware of the general and specific safety precautions of the establishment, mainly location of emergency exits and passageways, and where manufacturing, processing or storage of materials or products is taking place.

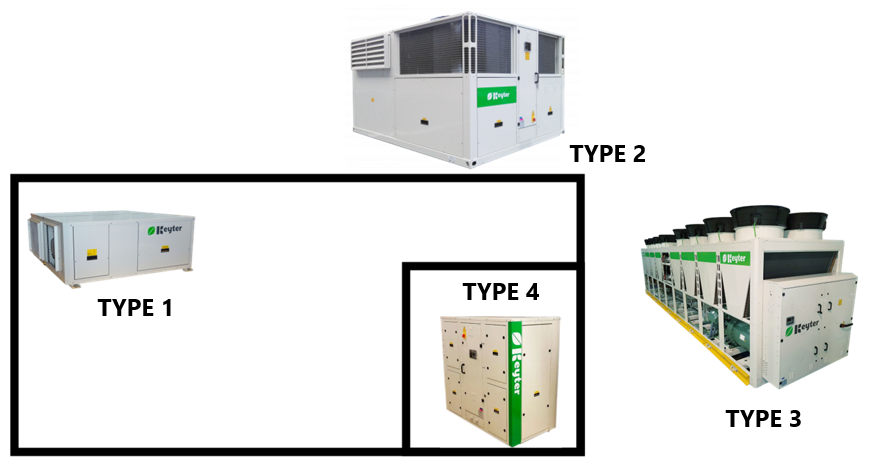

TYPE OF LOCATION

The location of the equipment within the building tells us how it will interact with the refrigerant in the event of a leak, so refrigeration systems are classified into four types:

“On the basis of safety criteria, refrigeration systems are classified into the following types, depending on their location:

- Type 1: Refrigeration system with all refrigerant containing parts located in a space occupied by people.

- Type 2: Refrigeration system with compressors, vessels and condensers located in an unoccupied machine room or in the open air. Chillers, piping and valves may be located in spaces occupied by people.

- Type 3: Refrigeration system with all refrigerant containing parts located in an unoccupied machine room or in the open air.

- Type 4: Refrigeration system where all refrigerant containing parts are located inside a ventilated enclosure.

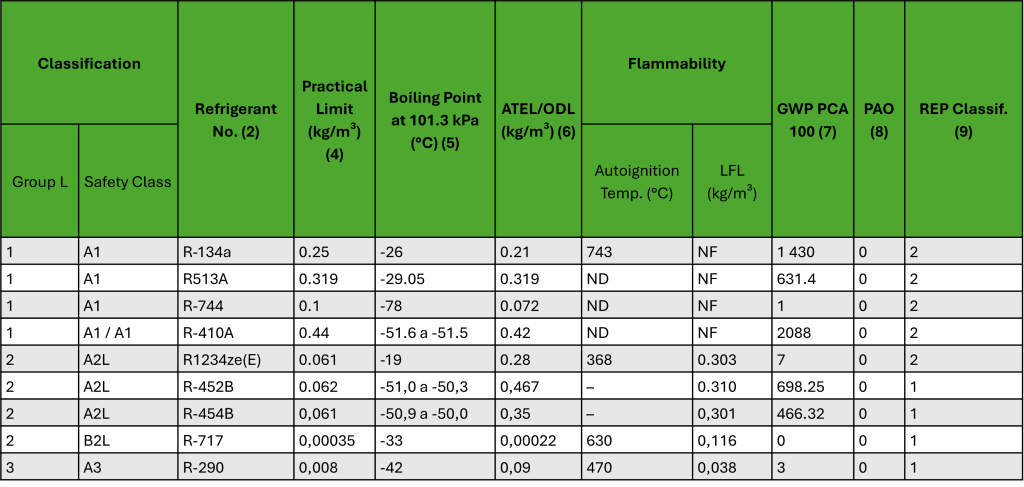

Where can we see this categorisation for each refrigerant in the RSIF? Appendix 1, Refrigerant Classification Table.

In it we find the column Safety Class, with the Toxicity/Flammability Classification.

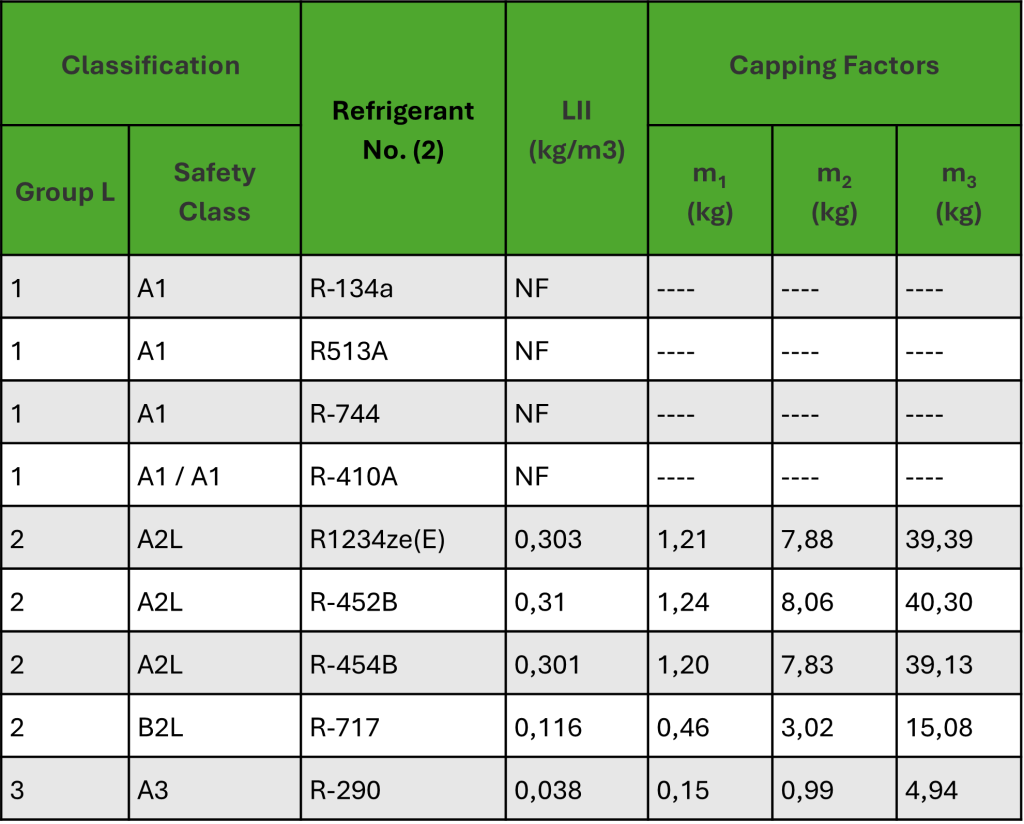

Refrigerant Table

Simplified for the Most Commonly Used Refrigerants in HVAC Systems

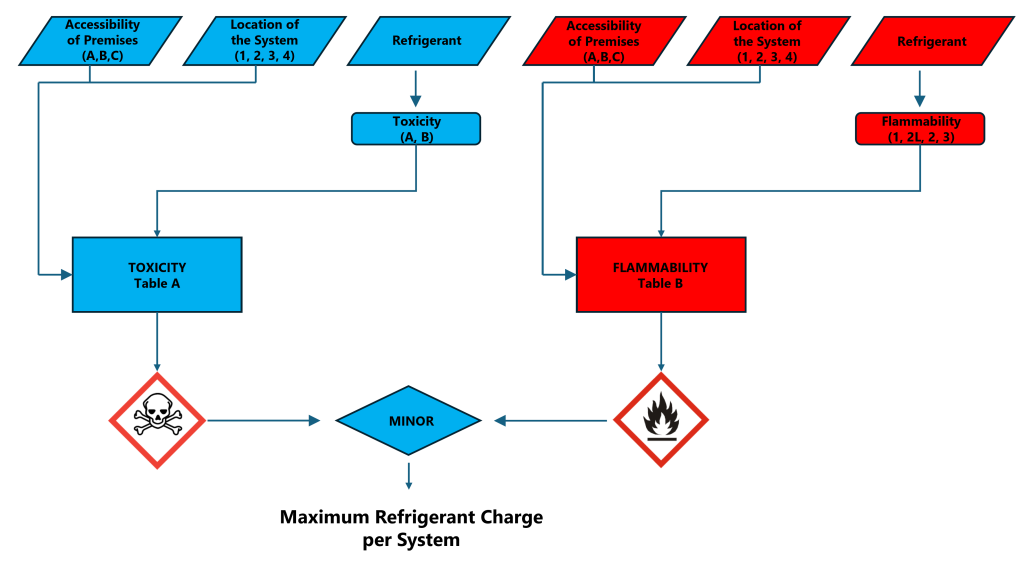

ESTIMATION OF THE MAXIMUM ALLOWABLE LOAD

The Maximum Refrigerant Load for Refrigeration Systems will be determined based on this parameter.

We emphasize the concept of a Refrigeration System, which is not the complete equipment. The definition of a Refrigeration System is:

“3. Definitions.

3.1 Refrigeration Systems.

3.1.1 Refrigeration Systems (including heat pumps)

A set of interconnected components containing refrigerant, which form a closed refrigeration circuit. Within this circuit, the refrigerant circulates to extract or transfer heat (i.e., cool or heat) to an external medium outside the refrigeration circuit.”

To determine this Maximum Refrigerant Load per System, we will rely on the following two tables:

Therefore, a single piece of equipment may include multiple Refrigeration Systems, each of which will be limited in its refrigerant capacity.

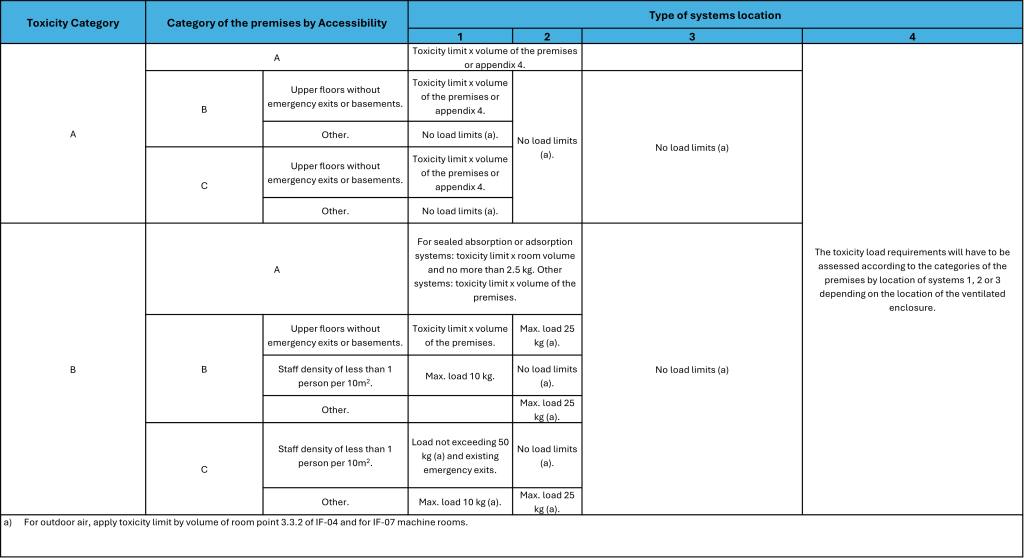

Table A

Load Limit Requirements for Refrigerants Based on Their Toxicity

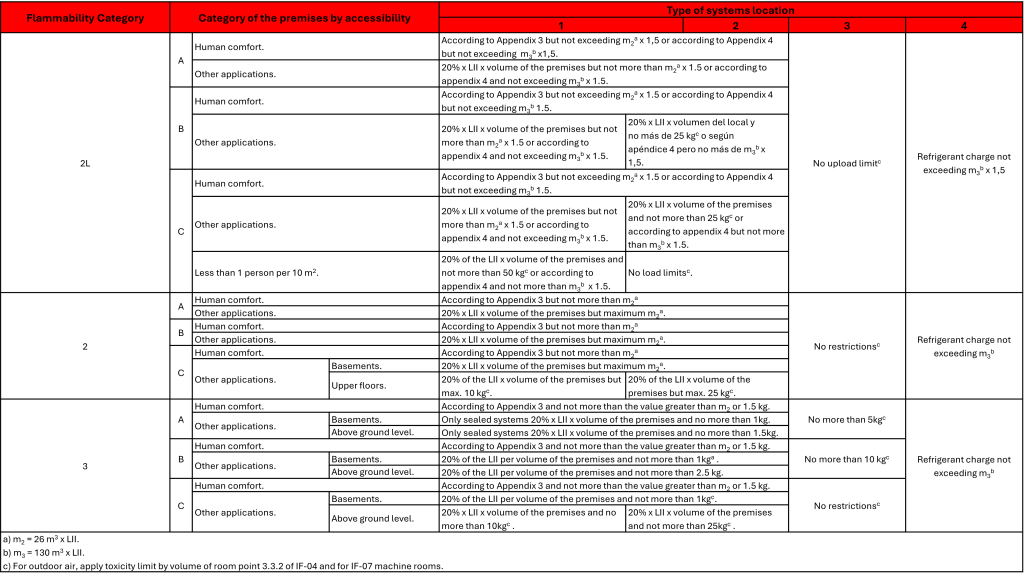

Table B

Load Limit Requirements for Refrigeration Systems Based on Flammability

When applying Table B, the following scenarios may arise:

Application of Limit Factors

These are as follows:

- m1 = 4 m3 × LII

- m2 = 26 m3 × LII

- m3 = 130 m3 × LII

Where the values of the Lower Flammability Limit (LFL) are those listed in Table A of Appendix 1 of IF-02, expressed in kg/m3. The multipliers 4, 26, and 130 are based on refrigerant loads of 150 g, 1 kg, and 5 kg of R-290 refrigerant.

For the most commonly used refrigerants, they are:

Limit Factors

Type 1 refrigerants are non-flammable, so they are not subject to this consideration. In fact, Table B does not include these refrigerants, as it applies starting from Type 2L.

Application of Appendix 3

In cases where there are parts containing refrigerant within an occupied space:

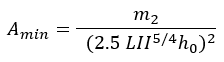

When the charge of a refrigerant with flammability category 2L exceeds the value of m1 × 1.5, the maximum allowable refrigerant charge for the space will be calculated using the following equation.

If the refrigerant charge with flammability category 2 or 3 exceeds m1, the maximum allowable charge in the space will be calculated using the following equation.

Alternatively, the minimum floor area Amin required to install the system with a charge of m (kg) will be calculated using the following equation.

Where:

mmáx is the maximum allowable charge in the space, in kg.

A is the area of the space, in m2.

Amin is the minimum floor area.

LII is the Lower Flammability Limit, in kg/m3.

ho is the installation height of the unit, in meters:

- 0.6 m for floor-mounted units.

- 1.8 m for wall-mounted units.

- 1.0 m for window units.

- 2.2 m for ceiling-mounted units.

There is another option, but it applies to non-fixed equipment, so it is not included here.

Application of Appendix 4

The application of this Appendix is complex and beyond the scope of this document. It can only be applied to installations that meet very specific requirements, including but not limited to:

- Refrigerants A1 or A2L.

- Location Type 2.

- Systems in which the cooling (heating) capacity of the indoor unit does not exceed 25% of the total cooling (heating) capacity of the outdoor units, and where the piping serving the equipment in the occupied space is not oversized relative to the equipment’s capacity.

- Systems where the refrigerant-containing parts of the indoor unit are protected against fan failure, or where the fan is designed to prevent breakage.

- …..

These types of calculations should not be performed without a deep understanding of RSIF. Therefore, we recommend their application be entrusted to experienced professionals.

CALCULATION METHOD

To perform the calculation, the following steps will be carried out:

- Determination of the Space Classification by Accessibility

- Determination of the System Location

TOXICITY CHARGE

– Determine the Toxicity Category based on the Refrigerant Table.

– Calculate the Toxicity Charge as the greatest of the following

- The maximum charge derived from Table A of Appendix 1 of this IF.

- 20m3 multiplied by the maximum charge for toxicity in hermetically sealed refrigeration systems.

- 150 g for hermetically sealed refrigeration systems using refrigerants in Toxicity Class A..

FLAMMABILITY CHARGE

– Determine the Flammability Category based on the Refrigerant Table.

– Calculate the Flammability Charge as the greatest of the following:

- The maximum charge derived from Table B of Appendix 1 of this IF.

- m1 x 1,5 for hermetically sealed refrigeration systems using Flammability Category 2L.

- m1 for hermetically sealed refrigeration systems using Flammability Categories 2 and 3.

- 150 g for hermetically sealed refrigeration systems.

Apply the lesser of the Toxicity Charge and the Flammability Charge

As derived from this document, the importance of refrigerant charge in Refrigeration Systems is very significant, particularly with Type 3 refrigerants, as it limits certain types of installations.

KEYTER has established itself as a leader in the HVAC+R sector, renowned for its ability to provide tailored solutions that address the current challenges in climate control. By integrating cutting-edge engineering with a personalized approach to each project, KEYTER delivers equipment designed to exceed expectations in performance, sustainability, and added value.

More articles

Interested in other (technical) knowledge articles? Keep yourself up to date and read them all