Energy Efficiency in Data Processing Centers (DPCs): Current Challenges and KEYTER’s Solutions for a Sustainable Future

Over the last three decades, the surge in demand for technological resources in the communication and information sector has been so significant that it has necessitated the rapid expansion of server rooms, storage systems, and related infrastructure to meet the growing requirements. High-density data processing centers (DPCs) now provide access to an almost infinite amount of information and services. However, this increase in the number and capacity of DPCs has led to greater consumption of space, water, and energy—resources that are often limited or scarce.

From an energy perspective, a large portion of the energy consumed by a DPC is converted into heat, requiring cooling systems that, in turn, consume a significant amount of electricity. This makes it imperative for cooling system manufacturers to provide solutions that not only reduce unavoidable energy consumption but also minimize the environmental impact of DPCs.

At KEYTER, we address this challenge through three main approaches:

- Enhancing the efficiency of chillers.

- Incorporating free cooling systems.

- Utilizing waste heat through heat recovery systems.

Improving chiller efficiency starts with the use of refrigerants with a very low Global Warming Potential (GWP). Reducing greenhouse gas emissions and improving machine efficiency are two sides of the same “coin,” which serves as a gateway to a more sustainable planet. To this end, all KEYTER machines are being adapted to use HFO or natural refrigerants with a GWP below 150. Additionally, optimized compressors are employed to enhance machine performance, even under extreme outdoor temperature conditions.

Leveraging natural elements for cooling IT rooms is a viable solution to reduce the energy consumption of DPCs. However, it is essential to consider the environmental consequences. Using aquifers as a heat sink or employing geothermal techniques requires a thorough impact assessment on the immediate surroundings. Similarly, dissipating heat into the air through “air free cooling” offers considerable savings, but it is important to evaluate how this thermal impact may affect nearby buildings, potentially causing effects similar to condenser battery heat emissions from chillers.

At KEYTER, we fully embrace the utilization of heat produced by DPCs. All our models are compatible with heat recovery systems, which can either partially or fully recover heat from the refrigeration circuit at the hot gas stage. Combining this with free cooling techniques can prevent the release of heat into the external environment, reducing the need for mechanical cooling. However, such solutions must be implemented from the project’s design or pre-design phase to maximize the use of generated heat.

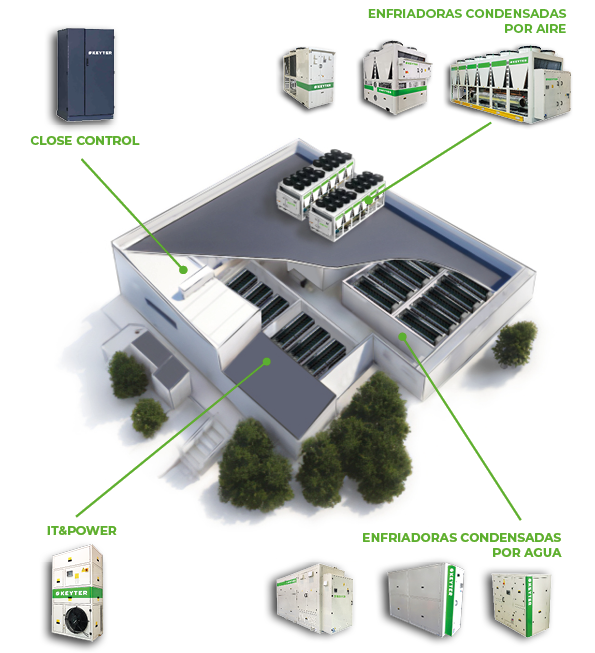

KEYTER’s comprehensive approach aligns with the adaptability of its machines to various situations. Starting from a standard configuration, customized solutions are developed to meet specific requirements. Not all options are applicable to every scenario, but KEYTER’s expertise and experience ensure the best solution is tailored to each unique need.

Cooling technologies for DPCs are undergoing a significant transformation, marking the advent of a second generation of cooling systems. These systems use direct liquid cooling for racks instead of air to transport heat within IT rooms. While air has low thermal inertia, allowing for rapid heating and cooling, its low heat capacity necessitates large circulating volumes to transport thermal energy. Water, with over four times the heat capacity of air, allows much smaller volumes to perform the same task. Moreover, liquid cooling can dissipate heat precisely at its source, offering near “surgical” precision.

KEYTER is incorporating new elements into its product catalog, such as “cold doors.” This initial step toward integrating electronic components enables the use of these new cooling methods, reducing energy consumption. By placing the heat exchanger directly on the rack, the need for large air volumes is eliminated, focusing only on the air contained within the racks. This reduces fan size and power, significantly improving system efficiency.

In addition to these available solutions, the integration of CDU systems or immersion cooling techniques are future challenges that KEYTER’s R&D department is addressing to complement the existing range of solutions.

KEYTER Technologies offers one of the most comprehensive ranges of solutions based on natural and low-GWP refrigerants, both for cooling and heating. Detailed information about these solutions and upcoming innovations is available through various communication channels (website, social media, digital press, etc.). Beyond the product itself, KEYTER’s vision includes providing added value through customer support—from offering solutions during the project design phase to technical assistance after installation, ensuring optimal performance in every situation.

More articles

Interested in other (technical) knowledge articles? Keep yourself up to date and read them all