Photovoltaic Heat Pump Hybridisation

When we talk about renewable energies, there is no doubt that the first concepts to come to mind are solar thermal and photovoltaic energy, others such as wind, geothermal or tidal energy, although we also know them, are secondary. But traditionally these two have been renewability queens. One that surely doesn’t come to mind, except for those of us who are initiated in this world of air conditioning, is the one generated by the Heat Pump (HP). The latest Regulation on Thermal Installations in Buildings (RTIB) modification endorses this, considering it partially renewable.

This new HP concept as partially renewable energy must be nurtured so in the near future its use will be commonplace. In this article we´ll be analyzing, just a quick look, how to make the partially renewable HP concept less and less partial.

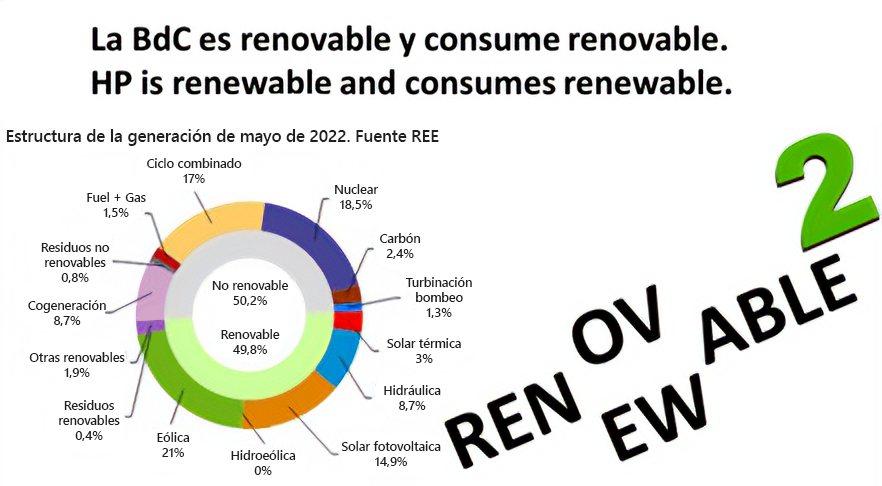

So far, none of the above renewable energies is capable of being, on its own, the definitive solution, so we take as a renewable source a mix of the above, and some others, to make our daily energy consumption more renewable. If we look data from Red Eléctrica Española, our electricity consumption is made up of 42.75% of this renewable energy mix. But what if we add HP to this mix?, What happens if we hybridise thermal energy, photovoltaics and HP? So we get, depending on the installation, a very close combination to what we could consider totally renewable.

Imagine if we were able to air-condition our buildings in this way, if we took 40 or 45% of the current electricity consumption out of the equation. Things would start to fits. Emissions would fall, Non-Renewable Primary Energy consumption would fall and our other sources dependence, until now considered NON-GREEN, would disappear.

This hybridisation can be carried out in three areas: air conditioning, DHW generation and industry.

Air Conditioning + Solar Photovoltaic

This combination is simple to understand because simply connecting a solar PV array to a PV array would not be enough, it gets complicated as PV array operation must be variable depending on PV array output. But that problem is already overcome since the EcoDesign Regulation has taught us to regulate by making the unit fully Inverter.

The compressors can be regulated by frequency inverters, so their operation, and therefore the cooling capacity, is entirely at our premises mercy.

In expansion, the electronic valves perfectly control evaporation according to compressor fluctuations. Reaction times are low and therefore the unit is very adaptable.

Fans have long been almost inverter, and nowadays they are inverter, which means that their operation is also adapted to every operating state.

In this way, we have a fully modular system. Therefore, we can make the HP system fully adaptable to the photovoltaic production and, if necessary, it can be fed from the electricity grid. This is the origin of concepts of Island Installation, which is only fed by the photovoltaic solar field, or Grid-connected, which is used when irradiance is low. Even the photovoltaic solar field, in mid-season or on low thermal load days, can feed this electricity production into the grid. We could work as an electrical District Heating, against other buildings or against other building installations. If we have a low thermal load, our lighting could be powered by the photovoltaic field and everything would stay at home.

Another way would be to accumulate electricity by means of batteries, it is completely possible, but it makes the solution very expensive, but… What if we accumulate in phase change? This technology already exists, or almost exists, to be able to accumulate electrical energy in a substance that changes phase and then returns that energy to the system sounds almost like science fiction, in a short time it will be just science, without any fiction.

KEYTER has already developed management software that controls this consumption by means of very precise photovoltaic production monitoring that generates optimal operating states within the HP. If the unit is powered by photovoltaics, it must be highly efficient, otherwise what is gained on one side is lost on the other. Each of the unit’s operating regimes must be adaptive, anticipating the generation trend. For this we have old acquaintances, the PID systems, which make it easier for us to generate these energy-efficient states.

DHW + Solar FV + Solar Thermal

The second step is DHW generation, for human use or as hot water for heating. If we already know how to feed a HP through photovoltaic, now we have to teach it that the inlet water temperature is variable, mains water or heating water, and we will get an unit that needs to compress less because the first step of water temperature is given by the solar thermal field. In the case of mains water at 10-12ºC, we could easily raise this temperature up to 45-50ºC, so the objective is almost achieved. In heating, with these temperatures we could also work with low temperature radiators, without problems. The hybridisation difficulty is the low DHW production of solar thermal field, but this first step has been achieved, and that´s no mean feat.

The reality is that, in certain locations, HP would only come in as auxiliary energy, the first step would be carried out by solar thermal field and if necessary HP would take the place of the traditional boiler but with the small detail of being renewable

Both hybridisation, solar photovoltaic and solar thermal, are already a fact. There are already solar thermal panels on the market such as Abora Solar that combine both technologies. They are photovoltaic and thermal, so the roof space is smaller, or energetically speaking, with the same surface area we generate twice as much. Another advantage of this panel type is that the water passage through them cools, or at least captures, some of the heat that lowers the photovoltaic generation efficiency. This point is important, as PV panels lose a lot of efficiency when they reach high temperatures, which is not desirable, this “cooling” optimises the system overall performance.

KEYTER has already developed units that also use this dual panel type with excellent performance for both DHW heating production, and in combination.

Industry + Solar FV + Solar Thermal

The next step is the industry, where the consumption is higher nowadays, although the requirements were lower in the past, nowadays an industrial process demands are very high. Industrial production cannot be stopped by a cloud passage, so island operation is not possible. How to overcome this problem?, In the case of high temperature storage, buffer storage tanks should be seen as energy storage tanks, not as hot water storage tanks for direct use. With high enough inertias we can achieve HP stable operation in very efficient operating states and therefore energy-efficient production.

Not only do we achieve this, the new refrigerants give us the possibility to generate hot water at 90ºC, or even steam at 120ºC, so the industry HP penetration is very deep. Processes that we thought unfeasible with HP not so many years ago, are now totally viable. With use of natural gas boilers is relegated to the background or almost tends to disappear.

This is the horizon we see from KEYTER, the complete elimination of non-renewable primary energy consumption through hybridised units and still offering higher performance than traditional systems.

There is no doubt that the journey has only just begun, new compression technologies with extended envelopes give plenty of scope for achieving the necessary high temperatures in hot water.

New refrigerants use, such as propane, opens up a new HP range that will make this possible. With the added bonus of being very low GWP (GWP – 3), which makes it perfect and durable in the face of new environmental requirements.

#HVACIsGreen #ChangeToGreen #TheGreenRevolution

Author: Jose J Arboledas

Keyter Training and Special Projects Manager

More articles

Interested in other (technical) knowledge articles? Keep yourself up to date and read them all