REFRIGERATORI ARIA-ACQUA – PRO SERIES – NESEA PRO KWFA

nesea proKWFA

Refrigeratori aria-acqua e pompe di calore per climi freddi | Alta temperatura fino a 75ºC

Documentazione

Caratteristiche

Tabella delle specifiche

Vedute e dimensioni

Controlli

Documentazione

Ecodesign

▸ Manuale di Ecodesign COMFORT KWFA

▸ Manuale di Ecodesign COMFORT KWFA

Caratteristiche

Pompe di calore aria-acqua adatte a climi freddi | Produzione di acqua fino a 75ºC

Disponibili in versioni solo riscaldamento, solo raffreddamento e reversibili, adatte per applicazioni residenziali o commerciali.

Nuova Serie PRO: Ottimizzata per l’uso del refrigerante R290 e della tecnologia Full-Inverter.

Adattamento e Ambiente

- Carica ridotta di refrigerante naturale R290, classe A3, ecologico con basso impatto ambientale (GWP = 3) e alte prestazioni termodinamiche. Disponibile anche con refrigerante R454C di classe A2L.

- Design robusto e affidabile con integrazione del rilevamento di perdite e ventola di estrazione ATEX per la massima sicurezza.

- Grazie a un isolamento accurato, garantiscono la protezione ottimale dell’attrezzatura e la riduzione del rumore, ottenendo un funzionamento ultra-silenzioso.

- Unità dotate di controllo intelligente che assicura un processo di sbrinamento ottimale.

Efficienza Energetica

- Unità compatte Full-Inverter dotate di compressore Scroll inverter ermetico, valvola di espansione elettronica e ventilatori EC che garantiscono le migliori prestazioni stagionali (SEER/SCOP).

- Ampio range operativo con elevata efficienza e limiti operativi estesi (funzionamento fino a -20ºC di temperatura esterna a pieno carico).

- Recupero parziale di calore disponibile con possibilità di integrazione della pompa di ricircolo.

Tabella delle specifiche

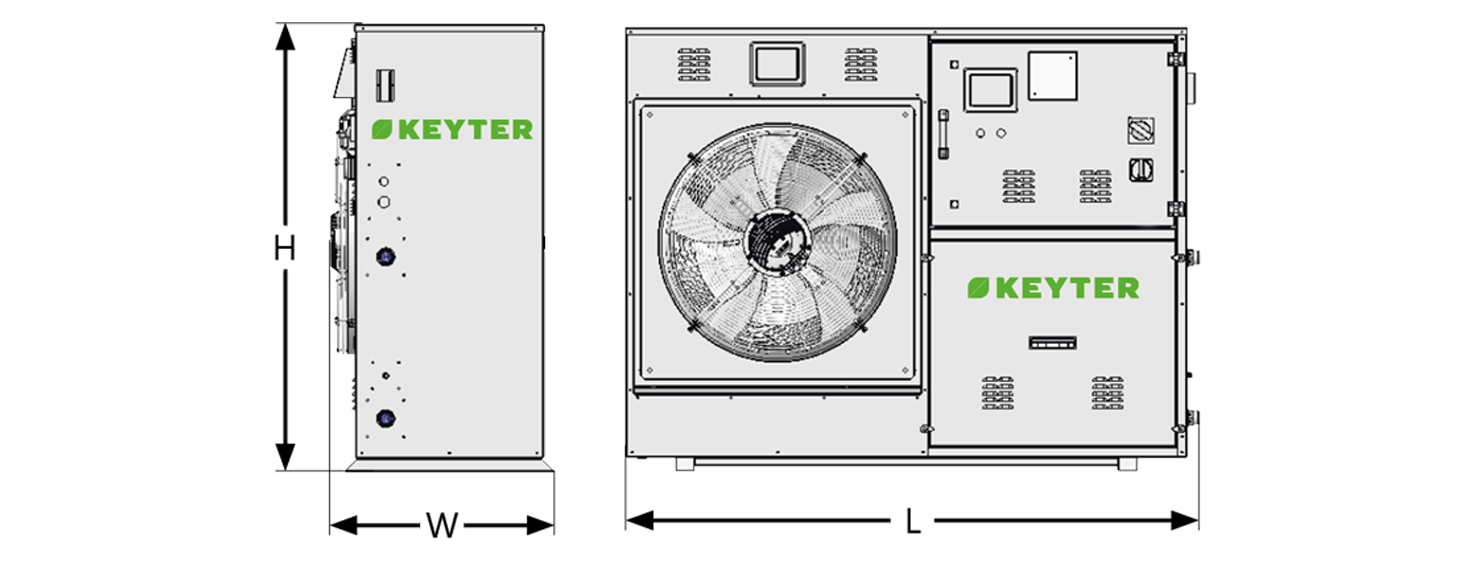

Vedute e dimensioni

Series 1 S/P

| Dimensioni standard dell’attrezzatura (mm) | |

|---|---|

| Carrozzeria | Series 1 S/P |

| L | 1670 |

| W | 600 |

| H | 1300 |

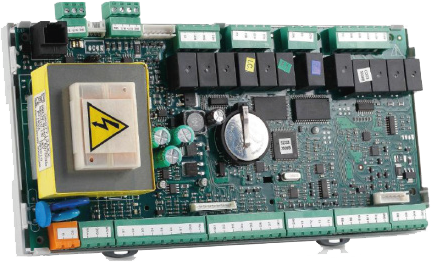

Controlli

NESEA PRO include il controllo elettronico programmabile AQUAMANAGER e il terminale utente pGD1.

È compatibile con la scheda RS485 opzionale per la comunicazione Modbus, con i sistemi di supervisione Boss/TERA e con il sistema di comunicazione BACNET/LONWORKS/KNX.

CONTATTACI

Come possiamo aiutarti?

Stai cercando soluzioni HVAC+R personalizzate o hai qualche domanda?

Non esitare a contattarci.