REFRIGERATORI ARIA-ACQUA – PRO SERIE – MEDEA PRO KZVB

medea proKZVB

Wasser-Wasser-Kaltwassersätze und Wärmepumpen mit einer Leistung von bis zu 77ºC

▸ Manuale di Ecodesign COMFORT KZVB

up to 77ºC

Available in heating-only, cooling-only, reversible, and reversible hydraulic circuit versions, designed for residential or commercial applications.

New PRO Series: Optimized for the use of R290 refrigerant

and Full-Inverter Technology.

Adaptation and Environment

- Reduced charge of natural R290 refrigerant, class A3, environmentally friendly with low environmental impact (GWP = 3) and high thermodynamic performance.

- Maximum versatility to integrate into new or existing systems: with fan coils, underfloor heating, radiators, or for domestic hot water production.

- Different hydraulic versions available, recirculation pumps on the external and/or internal side.

- With careful insulation, they ensure adequate protection of the equipment and reduce noise levels, achieving ultra-quiet operation.

Energy Efficiency

- Compact Full-Inverter units equipped with a hermetic Scroll inverter compressor, electronic expansion valve, and latest generation plate heat exchangers.

- Excellent power modulation allows achieving very high seasonal energy efficiency.

- Partial heat recovery is available with the possibility to integrate the recirculation pump.

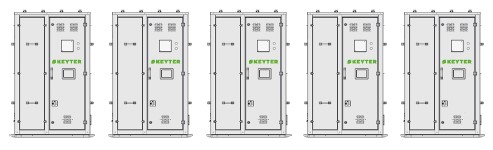

Cascade system

The Medea Pro heat pumps can be installed in a cascade configuration of up to 5 units in parallel, achieving a total modulation capacity in a single installation of:

- Total heating capacity up to 5 x 26 kW → up to 130 kW

- Total cooling capacity up to 5 x 22 kW → up to 110 kW

This simultaneous operation of the cascade system requires a rotating plate that allows for optimal management of the system.

The control management for cascade installations allows

for tracking the operating hours of each unit to extend their lifespan and prioritizes operation at partial load to optimize system performance.

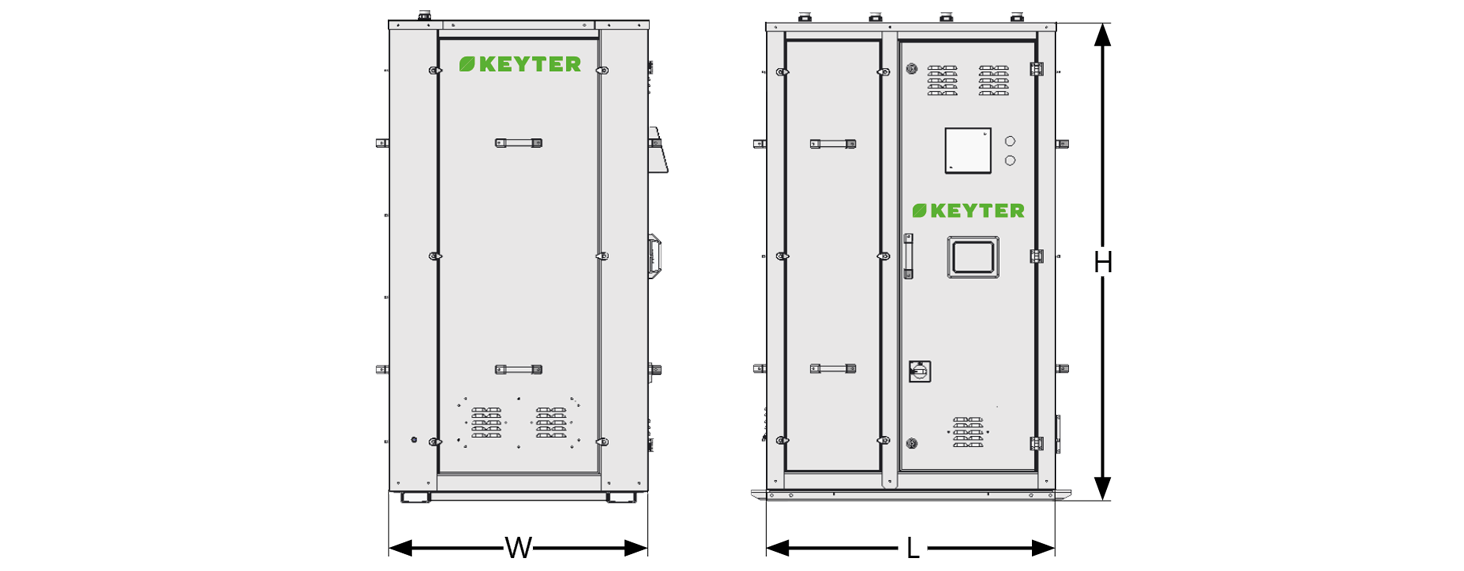

Series 1 S/P/H

| Standard equipment dimensions (mm) | |

|---|---|

| Bodywork | Series 1 S/P/H |

| L | 900 |

| W | 800 |

| H | 1500 |

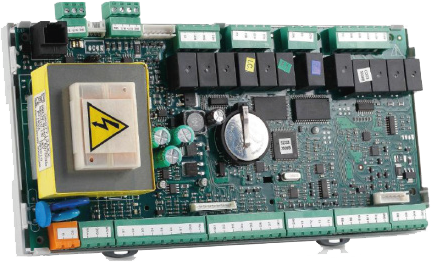

MEDEA PRO comprende il controllo elettronico programmabile AQUAMANAGER e il terminale utente pGD1.

È compatibile con la scheda RS485 opzionale per la comunicazione Modbus, con i sistemi di supervisione Boss/TERA e con il sistema di comunicazione BACNET/LONWORKS/KNX.

CONTATTACI

Come possiamo aiutarti?

Stai cercando soluzioni HVAC+R personalizzate o hai qualche domanda?

Non esitare a contattarci.